AC162078 Microchip Technology, AC162078 Datasheet - Page 174

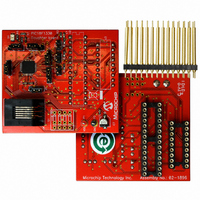

AC162078

Manufacturer Part Number

AC162078

Description

HEADER INTRFC MPLAB ICD2 18F1330

Manufacturer

Microchip Technology

Datasheet

1.AC162078.pdf

(318 pages)

Specifications of AC162078

Accessory Type

Transition Header

Lead Free Status / RoHS Status

Not applicable / Not applicable

For Use With/related Products

ICD2

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Not applicable / Not applicable

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

AC162078

Manufacturer:

MICROCHIP

Quantity:

12 000

- Current page: 174 of 318

- Download datasheet (3Mb)

PIC18F1230/1330

16.1

The A/D conversion can be triggered by setting the GO/

DONE bit. This bit can either be set manually by the

programmer or by setting the SEVTEN bit of ADCON0.

When the SEVTEN bit is set, the Special Event Trigger

from the Power Control PWM module triggers the A/D

conversion. For more information, see Section 14.14

“PWM Special Event Trigger”.

16.2

For the A/D Converter to meet its specified accuracy,

the charge holding capacitor (C

to fully charge to the input channel voltage level. The

analog input model is shown in Figure 16-3. The

source impedance (R

switch (R

required to charge the capacitor C

switch (R

(V

at the analog input (due to pin leakage current). The

maximum recommended impedance for analog

sources is 2.5 k. After the analog input channel is

EQUATION 16-1:

EQUATION 16-2:

EQUATION 16-3:

DS39758D-page 174

T

V

or

T

T

T

T

Temperature coefficient is only required for temperatures > 25C. Below 25C, T

T

T

ACQ

DD

C

ACQ

AMP

COFF

C

ACQ

HOLD

). The source impedance affects the offset voltage

=

=

Triggering A/D Conversions

A/D Acquisition Requirements

SS

=

=

=

=

=

SS

=

=

) impedance varies over the device voltage

Amplifier Settling Time + Holding Capacitor Charging Time + Temperature Coefficient

T

) impedance directly affect the time

AMP

T

0.2 s

(Temp – 25C)(0.02 s/C)

(85C – 25C)(0.02 s/C)

1.2 s

-(C

-(25 pF) (1 k + 2 k + 2.5 k) ln(0.0004883)

1.05 s

0.2 s + 1 s + 1.2 s

2.4 s

(V

-(C

AMP

HOLD

+ T

REF

HOLD

+ T

C

– (V

ACQUISITION TIME

A/D MINIMUM CHARGING TIME

CALCULATING THE MINIMUM REQUIRED ACQUISITION TIME

S

+ T

)(R

C

) and the internal sampling

)(R

+ T

REF

COFF

IC

IC

+ R

COFF

/2048)) • (1 – e

+ R

HOLD

SS

SS

HOLD

+ R

+ R

) must be allowed

S

S

) ln(1/2047)

. The sampling

) ln(1/2048)

(-T

C

/C

HOLD

(R

IC

+ R

SS

+ R

S

selected (changed), the channel must be sampled for

at least the minimum acquisition time before starting a

conversion.

To

Equation 16-1 may be used. This equation assumes

that 1/2 LSb error is used (1024 steps for the A/D). The

1/2 LSb error is the maximum error allowed for the A/D

to meet its specified resolution.

Example 16-3 shows the calculation of the minimum

required acquisition time, T

based

assumptions:

C

Rs

Conversion Error

V

Temperature

))

HOLD

DD

)

Note:

calculate

on

COFF

When the conversion is started, the

holding capacitor is disconnected from the

input pin.

the

= 0 ms.

the

=

=

=

=

following

minimum

2009 Microchip Technology Inc.

25 pF

2.5 k

1/2 LSb

5V R

85C (system max.)

ACQ

SS

. This calculation is

application

acquisition

= 2 k

system

time,

Related parts for AC162078

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet: