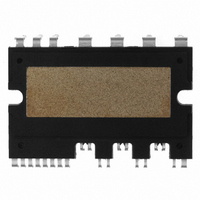

FSBB15CH60C Fairchild Semiconductor, FSBB15CH60C Datasheet - Page 56

FSBB15CH60C

Manufacturer Part Number

FSBB15CH60C

Description

IC POWER MOD SPM 600V SPM27CC

Manufacturer

Fairchild Semiconductor

Series

SPM™r

Type

IGBTr

Specifications of FSBB15CH60C

Configuration

3 Phase

Current

15A

Voltage

600V

Voltage - Isolation

2500Vrms

Package / Case

SPM27CC

Transistor Polarity

N Channel

Dc Collector Current

15A

Collector Emitter Voltage Vces

2V

Power Dissipation Pd

55W

Collector Emitter Voltage V(br)ceo

600V

Operating Temperature Range

-40°C To

Operating Temperature (max)

150C

Operating Temperature (min)

-40C

Pin Count

27

Mounting

Through Hole

Case Length

44mm

Case Height

5.5mm

Screening Level

Automotive

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

FSBB15CH60C

Manufacturer:

CYPRESS

Quantity:

5 610

Part Number:

FSBB15CH60C

Manufacturer:

FSC/ON可看货

Quantity:

20 000

10. Package

10.1 Heat Sink Mounting

device stress, when mounting an SPM on a heat sink.

2008-03-03

Heat Sink

Silicon Grease

Screw Tightening Torque

Heatsink Flatness

Mounting Torque

DBC Flatness

The following precautions should be observed to maximize the effect of the heat sink and minimize

Please follow the instructions of the manufacturer, when attaching a heat sink to an Mini DIP SPM. Be

careful not to apply excessive force to the device when attaching the heat sink.

Drill holes for screws in the heat sink exactly as specified. Smooth the surface by removing burrs and

protrusions of indentations. Refer to Table 10.1.

Heat-sink-equipped devices can become very hot when in operation. Do not touch, as you may sustain

a burn injury.

Apply silicon grease between the SPM and the heat sink to reduce the contact thermal resistance. Be

sure to apply the coating thinly and evenly, do not use too much. A uniform layer of silicon grease (100

~ 200um thickness) should be applied in this situation.

Do not exceed the specified fastening torque. Over tightening the screws may cause package cracks

and bolts and AL heat-fin destruction. Tightening the screws beyond a certain torque can cause

saturation of the contact thermal resistance. The tightening torques in table 10.1 is recommended for

obtaining the proper contact thermal resistance and avoiding the application of excessive stress to the

device.

Avoid stress due to tightening on one side only. Figure 10.1 shows the recommended torque order for

mounting screws. Uneven mounting can cause the SPM DBC substrate to be damaged.

Weight

Item

Mounting Screw : M3

Table 10.1 Torque Rating

(Note Fig. 10.1)

Condition

V4 Mini DIP SPM Application Note (2008-03-03)

Recommended

56

FAIRCHILD SEMICONDUCTOR - Smart Power Module

0.62 N⋅m

-100

Min.

0.51

0

-

Limits

15.40

0.62

Typ

-

+120

1.00

Max

+50

-

Unit

N⋅m

μm

μm

g