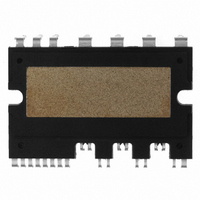

FSBB15CH60C Fairchild Semiconductor, FSBB15CH60C Datasheet - Page 52

FSBB15CH60C

Manufacturer Part Number

FSBB15CH60C

Description

IC POWER MOD SPM 600V SPM27CC

Manufacturer

Fairchild Semiconductor

Series

SPM™r

Type

IGBTr

Specifications of FSBB15CH60C

Configuration

3 Phase

Current

15A

Voltage

600V

Voltage - Isolation

2500Vrms

Package / Case

SPM27CC

Transistor Polarity

N Channel

Dc Collector Current

15A

Collector Emitter Voltage Vces

2V

Power Dissipation Pd

55W

Collector Emitter Voltage V(br)ceo

600V

Operating Temperature Range

-40°C To

Operating Temperature (max)

150C

Operating Temperature (min)

-40C

Pin Count

27

Mounting

Through Hole

Case Length

44mm

Case Height

5.5mm

Screening Level

Automotive

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

FSBB15CH60C

Manufacturer:

CYPRESS

Quantity:

5 610

Part Number:

FSBB15CH60C

Manufacturer:

FSC/ON可看货

Quantity:

20 000

9.4 Heat Sink Design Guide

dissipation, heat sink cost, flow condition around a heat sink, assembly location, etc. In this note, only some

of the constraints are analyzed to give some insights in heat sink selection from a practical application point

of view.

machine applications that have drive characteristics in which the power dissipated is alternatively high and

low over periods of hundreds of milli-seconds in the SPM.

designing the heat sink. This varies widely with the changes in fin spacing, fin/base-plate length and fin/base-

plate width. It should be noted that the optimum fin spacing is approximately 4 or 5 mm with a base-plate

area of 73 × 53 mm

number of fins, i.e., the total convection area. Reducing the fin spacing interferes with the airflow field

between the adjacent fins. This causes an increase in the thermal resistance when the fins are spaced below

and above 4mm and 5mm, respectively. An increase in fin thickness decreases the total number of fins and

the size of the heat sink, resulting in an increase in thermal resistance.

2008-03-03

Heat Sink for Use in Washing Machines

The selection of a heat sink is constrained by many factors including set space, actual operating power

The type of heat sink shown in Fig. 9.9 can be applied under natural convection conditions in washing

Figures 9.10 - 9.13 show the analysis results for the heat sink-to-ambient thermal resistance, R

2

, as shown in Fig. 9.10. Increasing the fin spacing results in a reduction of the total

Figure 9.9 A heat sink example for washing machines applications.

e = Base-plate thickness, f = Base-plate width, g = Base-plate length

a = Fin thickness, b = Fin spacing, c = Fin height, d = Fin length,

f

V4 Mini DIP SPM Application Note (2008-03-03)

52

FAIRCHILD SEMICONDUCTOR - Smart Power Module

c

e

a

d, g

b

θ

ha

, in