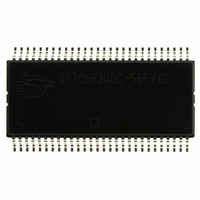

CY7C68300C-56PVXC Cypress Semiconductor Corp, CY7C68300C-56PVXC Datasheet - Page 41

CY7C68300C-56PVXC

Manufacturer Part Number

CY7C68300C-56PVXC

Description

IC USB 2.0 BRIDGE AT2LP 56-SSOP

Manufacturer

Cypress Semiconductor Corp

Series

CY7Cr

Type

USB to ATA/ATAPI Bridger

Datasheets

1.CY7C68300C-56PVXC.pdf

(42 pages)

2.CY7C68320C-100AXA.pdf

(44 pages)

3.CY7C68300C-56PVXC.pdf

(42 pages)

Specifications of CY7C68300C-56PVXC

Package / Case

56-SSOP

Controller Type

USB 2.0 Controller

Interface

I²C

Voltage - Supply

3.15 V ~ 3.45 V

Current - Supply

50mA

Operating Temperature

0°C ~ 70°C

Mounting Type

Surface Mount

Maximum Operating Temperature

+ 70 C

Minimum Operating Temperature

0 C

Mounting Style

SMD/SMT

Number Of Bits

48

Operating Temperature Range

0 C to + 70 C

Supply Current

10 mA

Operating Supply Voltage

3.3 V

Controller Family/series

(8051) USB

Core Size

8 Bit

No. Of I/o's

6

Embedded Interface Type

I2C, USB

Digital Ic Case Style

SSOP

Supply Voltage Range

3V To 3.6V

Rohs Compliant

Yes

Operating Temperature (min)

0C

Operating Temperature Classification

Commercial

Operating Temperature (max)

70C

Package Type

SSOP

Rad Hardened

No

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With

CY4615B - KIT USB TO ATA REFERENCE DESIGN

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

428-2266-5

CY7C68300C-56PVXC

CY7C68300C-56PVXC

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

CY7C68300C-56PVXC

Manufacturer:

HITACHI

Quantity:

2 000

Company:

Part Number:

CY7C68300C-56PVXC

Manufacturer:

CY

Quantity:

8

Part Number:

CY7C68300C-56PVXC

Manufacturer:

CYPRESS/赛普拉斯

Quantity:

20 000

For further information on this package design, refer to the

application note Surface Mount Assembly of AMKOR’s

MicroLeadFrame (MLF) Technology. The application note

provides detailed information on board mounting guidelines,

soldering flow, rework process, and so on.

Figure 16

Other Design Considerations

Certain design considerations must be followed to ensure proper

operation of the CY7C68300C/CY7C68301C. The following

items must be taken into account when designing a USB device

with the CY7C68300C/CY7C68301C.

Proper Power Up Sequence

Power must be applied to the CY7C68300C/CY7C68301C

before, or at the same time as the ATA/ATAPI device. If power is

supplied to the drive first, the CY7C68300C/CY7C68301C

startup in an undefined state. Designs that use separate power

supplies for the CY7C68300C/CY7C68301C and the ATA/ATAPI

device are not recommended.

Document Number: 001-05809 Rev. *H

Figure 16. Plot of the Solder Mask (White Area)

is a plot of solder mask pattern and

Via hole for thermally connecting the

QFN to the circuit board ground plane.

PCB Material

Figure 15. Cross-Section of the Area Under the QFN Package

Figure 17

Cu Fill

displays an X-Ray image of assembly (darker areas indicate solder).

Solder Mask

0.013” dia

0.017” dia

Figure 15

package. The cross section is of only one via. The solder paste

template needs to be designed to enable at least 50% solder

coverage. The thickness of the solder paste template must be

5 mil. It is recommended that ’No Clean,’ type 3 solder paste is

used to mount the part. Nitrogen purge is recommended during

reflow.

IDE Removable Media Devices

The AT2LP does not fully support IDE removable media devices.

Changes in media state are not reported to the operating system

so users are unable to eject or reinsert media properly. This may

result in lost or corrupted data. Note that standard ATAPI optical

drives and ATA CompactFlash-type devices are not part of this

group.

Devices With Small Buffers

The size of the drive’s buffer can greatly affect the overall data

transfer performance. Ensure that drives have large enough

buffers to handle the flow of data to and from it. The exact buffer

size needed depends on a number of variables, but a good rule

of thumb to follow is:

(approx min buffer) = (data rate) * (seek time + rotation time + other)

where ’other’ may include things such as the time required to

switch heads and power up a laser. Drives with buffers that are

too small to handle the extra data may perform considerably

slower than expected.

This figure only shows the top three layers of the

circuit board: Top Solder, PCB Dielectric, and

the Ground Plane

Cu Fill

PCB Material

Figure 17. X-Ray Image of the Assembly

displays a cross-sectional area underneath the

CY7C68300C, CY7C68301C

CY7C68320C, CY7C68321C

Page 41 of 44

[+] Feedback