AD9516-1/PCBZ Analog Devices Inc, AD9516-1/PCBZ Datasheet - Page 37

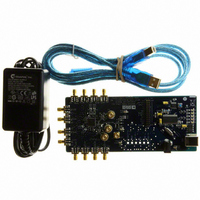

AD9516-1/PCBZ

Manufacturer Part Number

AD9516-1/PCBZ

Description

BOARD EVALUATION FOR AD9516-1

Manufacturer

Analog Devices Inc

Specifications of AD9516-1/PCBZ

Main Purpose

Timing, Clock Generator

Embedded

No

Utilized Ic / Part

AD9516-1

Primary Attributes

2 Inputs, 14 Outputs, 2.5GHz VCO

Secondary Attributes

CMOS, LVDS, LVPECL Output Logic, ADIsimCLK™ Graphical User Interface

Silicon Manufacturer

Analog Devices

Application Sub Type

PLL Clock Synthesizer

Kit Application Type

Clock & Timing

Silicon Core Number

AD9516-0, AD9516-1, AD9516-2

Silicon Family Name

AD9516-X

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Holdover

The AD9516 PLL has a holdover function. Holdover is

implemented by putting the charge pump into a state of high

impedance. This is useful when the PLL reference clock is lost.

Holdover mode allows the VCO to maintain a relatively constant

frequency even though there is no reference clock. Without this

function, the charge pump is placed into a constant pump-up or

pump-down state resulting in a massive VCO frequency shift.

Because the charge pump is placed in a high impedance state,

any leakage that occurs at the charge pump output or the VCO

tuning node causes a drift of the VCO frequency. This can be

mitigated by using a loop filter that contains a large capacitive

component because this drift is limited by the current leakage

induced slew rate (I

applications, the frequency accuracy is sufficient for 3 sec to 5 sec.

Both a manual holdover, using the SYNC pin, and an automatic

holdover mode are provided. To use either function, the

holdover function must be enabled (Register 0x01D[0] and

Register 0x01D[2]).

Note that the VCO cannot be calibrated with the holdover

enabled because the holdover resets the N divider during

calibration, which prevents proper calibration. Disable holdover

before issuing a VCO calibration.

Manual Holdover Mode

A manual holdover mode can be enabled that allows the user to

place the charge pump into a high impedance state when the

SYNC pin is asserted low. This operation is edge sensitive, not

level sensitive. The charge pump enters a high impedance state

immediately. To take the charge pump out of a high impedance

state take the SYNC pin high. The charge pump then leaves

high impedance state synchronously with the next PFD rising

edge from the reference clock. This prevents extraneous charge

pump events from occurring during the time between SYNC

going high and the next PFD event. This also means that the

charge pump stays in a high impedance state as long as there is

no reference clock present.

The B-counter (in the N divider) is reset synchronously with

the charge pump leaving the high impedance state on the

reference path PFD event. This helps align the edges out of the

R and N dividers for faster settling of the PLL. Because the

prescaler is not reset, this feature works best when the B and R

numbers are close because this results in a smaller phase

difference for the loop to settle out.

When using this mode, set the channel dividers to ignore the

SYNC pin (at least after an initial SYNC event). If the dividers are

not set to ignore the SYNC pin, the distribution outputs turn off

each time SYNC is taken low to put the part into holdover.

LEAK

/C) of the VCO control voltage. For most

Rev. A | Page 37 of 80

Automatic/Internal Holdover Mode

When enabled, this function automatically puts the charge

pump into a high impedance state when the loop loses lock.

The assumption is that the only reason the loop loses lock is due

to the PLL losing the reference clock; therefore, the holdover

function puts the charge pump into a high impedance state to

maintain the VCO frequency as close as possible to the original

frequency before the reference clock disappears.

See Figure 53 for a flowchart of the internal/automatic holdover

function operation.

HIGH IMPEDANCE

HIGH IMPEDANCE

WHEN DLD WENT

LD PIN == HIGH

CHARGE PUMP

CHARGE PUMP

EDGE AT PFD?

PLL ENABLED

DLD == LOW

DLD == HIGH

REFERENCE

RELEASE

LOW?

Figure 53. Flowchart of Automatic/Internal Holdover Mode

WAS

YES

YES

YES

YES

YES

NO

NO

NO

NO

YES

LOOP OUT OF LOCK. DIGITAL LOCK

DETECT SIGNAL GOES LOW WHEN THE

LOOP LEAVES LOCK AS DETERMINED

BY THE PHASE DIFFERENCE AT THE

INPUT OF THE PFD.

ANALOG LOCK DETECT PIN INDICATES

LOCK WAS PREVIOUSLY ACHIEVED.

REGISTER 0x1D[3] = 1: USE LD PIN

VOLTAGE WITH HOLDOVER.

REGISTER 0x1D[3] = 0: IGNORE LD PIN

VOLTAGE,TREAT LD PIN AS ALWAYS HIGH.

CHARGE PUMP IS MADE

HIGH IMPEDANCE.

PLL COUNTERS CONTINUE

OPERATING NORMALLY.

CHARGE PUMP REMAINS HIGH

IMPEDANCE UNTIL THE REFERENCE

HAS RETURNED.

TAKE CHARGE PUMP OUT OF

HIGH IMPEDANCE. PLL CAN

NOW RESETTLE.

WAIT FOR DLD TO GO HIGH. THIS TAKES

5 TO 255 CYCLES (PROGRAMMING OF

THE DLD DELAY COUNTER) WITH THE

REFERENCE AND FEEDBACK CLOCKS

INSIDE THE LOCK WINDOW AT THE PFD.

THIS ENSURES THAT THE HOLDOVER

FUNCTION WAITS FOR THE PLL TO SETTLE

AND LOCK BEFORE THE HOLDOVER

FUNCTION CAN BE RETRIGGERED.

AD9516-1