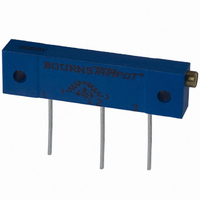

3059Y-1-500LF Bourns Inc., 3059Y-1-500LF Datasheet - Page 154

3059Y-1-500LF

Manufacturer Part Number

3059Y-1-500LF

Description

TRIMPOT 50 OHM 1.25"REC CER MT

Manufacturer

Bourns Inc.

Series

3059 - Sealedr

Specifications of 3059Y-1-500LF

Temperature Coefficient

±100ppm/°C

Resistance (ohms)

50

Termination Style

PC Pin

Power (watts)

1W

Tolerance

±10%

Number Of Turns

22

Adjustment Type

Side Adjustment

Resistive Material

Cermet

Mounting Type

Chassis Mount

Package / Case

Rectangular - 1.250" L x 0.190" W x 0.315" H (31.75mm x 4.83mm x 8.00mm)

Track Resistance

50ohm

No. Of Turns

22

Resistance Tolerance

± 10%

Power Rating

1W

Potentiometer Mounting

Through Hole

Resistance

50 Ohms

Operating Temperature Range

- 55 C to + 150 C

Element Type

Cermet

Dimensions

6.10 mm W x 31.75 mm L

Product

Trimmers

Taper

Linear

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Applications/Processing Guide – Standard and Lead Free

Processability

“Processability” refers to the ability of the unit to withstand the

production-line processes associated with the finishing steps on

the PC boards. Typically, both SMT and through-hole products

are subjected to similar PC board processing operations after

preparation for assembly. These operations can generally be

summarized as follows:

Soldering (SMT)

Four types of equipment are usually associated with SMT

soldering:

Soldering (Through-hole)

Two types of equipment are usually associated with through-hole

soldering:

152

IR System — Uses a multi-zone infrared furnace with IR

elements heated to a temperature substantially above chamber

or product temperature. Energy is supplied to the product

primarily by IR radiation to reflow solder.

Forced Hot Air Convection System — Uses a multizone forced

air convection system with heat source panels using IR or

other type heating elements. Approximately 85 % of the

heating is provided by free convection to reflow solder on

exposed PC boards.

Dual Wave System — Utilizes two parallel solder waves. The

first is a turbulent wave followed by a laminar wave. The

turbulent wave is for small, constricted areas, while the

laminar wave removes solder projections.

Vapor Phase System — Provides a single-zone condensation

heat source achieved with liquid fluorinated hydrocarbons

that have been brought to the boiling point to create a

saturated vapor zone. Heat is then released by the fluid’s heat

of vaporization as the vapor condenses on the product.

Single Wave System — Provides an inclined portion of the

solder wave for the PC board to pass over. The PC board is

positioned to bring many potential solder joints in contact

with the wave simultaneously for a short time for soldering.

Drag System — Provides for PC boards to be dragged across

the surface of the solder pot. Soldered connections are made

during this operation.

WASH

FLUX

PRE-HEAT

RINSE

SOLDER

DRY

PC Board Washing

Two types of equipment are usually associated with both SMT

and through-hole products.

Soldering and Wash Processes

Figure 1 shows typical profiles any component may see during a

soldering and board washing operation. For details of material

and process variables recommendations, see “Soldering and

Cleaning Processes”, page 152.

°C/Min.

°C

Critical profile parameters

1

2

3

4

Pressure System — Accomplishes cleaning by directing sprays

of water under high pressure from multiple nozzles.

Flooding System — Utilizes a combination of flooding (at

normal water pressure) and surfactant action for cleaning.

Temperature Shock (°C)

Maximum Temperature (°C)

Temperature Exposure (Minimum)

Temperature Gradient (°C)

Typical temperature profile for board washing and soldering.

1

3

2

4

(Indicator of Level of Stability)

5

Rate of Change of Profile

Minutes

Minutes

Figure 1

5

6

7

Temperature Shock Decrease in Water (°C)

Temperature Shock Decrease in Water

& Air Pressure (°C)

Unstable Temperature

6

7

Unstable Temp.

(# of Cycles)

Top

Mounted

Thermocouple

Bottom

Mounted

Thermocouple