QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 69

QDE-825D

Manufacturer Part Number

QDE-825D

Description

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

PSDI (Presence-Sensing Device Initiation): An application

in which a presence-sensing device is used to actually start

the cycle of a machine. In a typical situation, an operator

manually positions a part in the machine for the operation.

When the operator moves out of the danger area, the presence-

sensing device starts the machine (no start switch is used).

The machine cycle runs to completion, and the operator can

then insert a new part and start another cycle. The presence-

sensing device continually guards the machine. Single-break

mode is used when the part is automatically ejected after the

machine operation. Double-break mode is used when the part

is both inserted (to begin the operation) and removed (after the

operation) by the operator. PSDI is commonly confused with

“Trip Initiate.” PSDI is defined in OSHA CFR1910.217. Banner

safety light screen systems may not be used as PSDI devices

on mechanical power presses, per OSHA regulation 29 CFR

1910.217.

Qualified Person: An individual who, by possession of a

recognized degree or certificate of professional training, or by

extensive knowledge, training, and experience, has successfully

demonstrated the ability to solve problems relating to the subject

matter and work. (See Designated Person.)

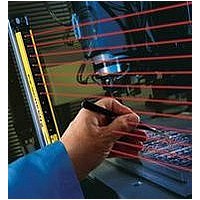

Receiver: The light-receiving component of a safety light screen

system, consisting of a row of synchronized phototransistors.

The receiver, together with the emitter (placed opposite),

creates a “screen of light” called the defined area.

Reduced Resolution: A feature that allows a safety light

screen system to be configured to produce an intentionally

disabled light beam(s) within the light screen, which increases

the minimum object sensitivity. The disabled beam(s) appears

to move up and down (“float”) in order to allow the feeding of

an object through the defined area at any point without tripping

the safety outputs (e.g., OSSDs) and causing a Trip or Latch

condition. Sometimes called “Floating Blanking.”

Reset: The use of a manually operated switch to restore

the safety outputs to the ON state from a lockout or a Latch

condition.

Resolution: See Minimum Object Sensitivity.

Self-Checking (Circuitry): A circuit with the capability to

electronically verify that all of its own critical circuit components,

along with their redundant backups, are operating properly.

Banner safety light screen systems and safety modules are self-

checking.

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Separation Distance (Safety Light Screen): The minimum

distance required to allow the machine’s hazardous motion

to stop completely, before a hand (or other object) can reach

the nearest hazard point. Measured from the midpoint of the

defined area to the nearest hazard point. Factors that influence

minimum separation distance include the machine stop time,

the light screen system response time, and the light screen

minimum object detection size.

Specified Test Piece: An opaque object of sufficient size used

to block a light beam to test the operation of a safety light

screen system. When inserted into any part of the defined area,

it will place a system into a Trip or Latch condition. Banner

supplies specified test pieces with each system. See also

Minimum Object Sensitivity.

Supplemental Guarding: Additional safeguarding device(s) or

hard guarding, used to prevent a person from reaching over,

under, through or around the primary safeguard or otherwise

accessing the guarded hazard.

Test Piece: An opaque object of sufficient size used to block a

light beam to test the operation of a safety light screen system.

Trip Condition: The response of the safety outputs (e.g.,

OSSDs) of a safety light screen system when an object equal

to or greater than the diameter of the specified test piece enters

the defined area. In a Trip condition, the OSSDs simultaneously

de-energize. A Trip condition clears (resets) automatically

when the object is removed from the defined area. (See Latch

Condition.)

Trip Initiate: The resetting of a safeguard causing the initiation

of machine motion or operation. Trip Initiate is not allowed

as a means to initiate a machine cycle per NFPA 79 and ISO

60204-1, and is commonly confused with PSDI.

UL (Underwriters Laboratory): A third-party organization

that tests products for compliance with appropriate standards,

electrical codes, and safety codes. Compliance is indicated by

the UL listing mark on the product.

Glossary

Overview

P/N 112852 rev. F

P/N 133487

67

67