QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 53

QDE-825D

Manufacturer Part Number

QDE-825D

Description

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

The EZ-SCREEN is designed and manufactured to be highly

resistant to electrical and optical noise and to operate reliably

in industrial settings. However, serious electrical and/or optical

noise may cause a random Trip or Latch condition. In very

extreme electrical noise cases, a Lockout is possible. In order

to minimize the effects of transitory noise, the EZ-SCREEN

will respond to noise only if the noise is detected on multiple

consecutive scans.

If random nuisance Trips occur, check the following:

• Poor connection between the sensor and earth ground;

• O ptical interference from adjacent light screens or other

• S ensor input or output wires routed too close to “noisy” wiring.

Checking for sources of electrical noise: It is very important

that the light screen sensors have a good earth ground. Without

this, the System can act like an antenna and random Trips and

Lockouts can occur.

All EZ-SCREEN wiring is low voltage; running these wires

alongside power wires, motor/servo wires, or other high-voltage

wiring, can inject noise into the EZ-SCREEN system. It is good

wiring practice (and may be required by code) to isolate

EZ-SCREEN wires from high-voltage wires.

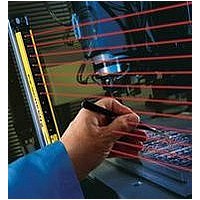

The Banner model BT-1 Beam Tracker (see Section 2.4) is

a very good tool for detecting electrical noise. It can be used

to detect electrical transient spikes and surges. Cover the

lens of the BT-1 with electrical tape to block optical light from

getting into the receiver lens. Press the “RCV” button on the

BT-1 and position the Beam Tracker on the wires going to the

EZ-SCREEN or any other nearby wires. Noise caused by the

switching of inductive loads should be addressed by installing

proper transient suppression across the load.

Checking for sources of optical noise: Turn off the emitter,

completely block the emitter, or open the Test input, then use

a Banner BT-1 Beam Tracker to check for light at the receiver.

Press the “RCV” button on the BT-1 and move it across the full

length of the receiver’s sensing window. If the BT-1’s indicator

lights, check for light from other sources (other safety light

screens, screens or points, or standard photoelectric sensors) by

“tracking down” the emitted light from them.

photoelectrics; or

5.3 Electrical and Optical Noise

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Cleaning

EZ-SCREEN emitters and receivers are constructed of

aluminum with a yellow painted finish and are rated IP65. Lens

covers are acrylic. Emitters and receivers are best cleaned

using mild detergent or window cleaner and a soft cloth. Avoid

cleaners containing alcohol, as they may damage the acrylic

lens covers.

Warranty Service

EZ-SCREEN components are designed for reliability. Do not

open the emitter or receiver housings, other than to access for

configuration. They contain no field-replaceable components.

If repair is necessary, do not attempt to repair an emitter or

receiver yourself; return the unit to the factory.

Should it become necessary to return an EZ-SCREEN

component to the factory, please do the following:

1. Contact the Banner Factory Application Engineering group at

2. Pack the component(s) carefully. Damage which occurs

5.4 Servicing and Maintenance

the address or numbers listed below:

during return shipping is not covered by warranty.

They will attempt to troubleshoot the system from your

description of the problem. If they conclude that a component

is defective, they will issue an RMA (Return Merchandise

Authorization) number for your paperwork, and give you the

proper shipping address.

Banner Engineering Corp.,

Application Engineering Group

9714 Tenth Avenue North

Minneapolis, MN 55441

Phone: 763.544.3164 or

Toll-Free (US only): 888.373.6767

email: sensors@bannerengineering.com

Troubleshooting and Maintenance

Overview

P/N 112852 rev. F

P/N 133487

51

51