LTM4618IV#PBF Linear Technology, LTM4618IV#PBF Datasheet - Page 19

LTM4618IV#PBF

Manufacturer Part Number

LTM4618IV#PBF

Description

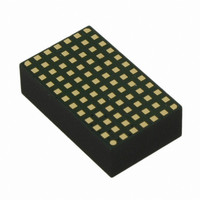

IC DC-DC UMODULE BUCK 6A 84-LGA

Manufacturer

Linear Technology

Series

µModuler

Type

Point of Load (POL) Non-Isolatedr

Datasheet

1.LTM4618EVPBF.pdf

(24 pages)

Specifications of LTM4618IV#PBF

Output

0.8 ~ 5 V

Number Of Outputs

1

Power (watts)

30W

Mounting Type

Surface Mount

Voltage - Input

4.5 ~ 26.5 V

Package / Case

84-LGA

1st Output

0.8 ~ 5 VDC @ 6A

Size / Dimension

0.59" L x 0.35" W x 0.17" H (15mm x 9mm x 4.32mm)

Power (watts) - Rated

30W

Operating Temperature

-40°C ~ 125°C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3rd Output

-

2nd Output

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

APPLICATIONS INFORMATION

EMI Section

The LTM4618 has been evaluated for CISPR22 A and B

Radiated EMI and CISPR25 Conducted EMI. The CISPR25

Conducted EMI test was performed with an input π fi lter

as shown in Figure 17. An RC snubber circuit is optionally

used from the SW pin to the PGND pin to improve the higher

frequency attenuation and EMI limit guard band. Figure 18

shows the CISPR25 conducted emissions plot for 26.5V

input to 3.3V output at 5A load. Several conditions were

evaluated, and Figure 18 results are from the worst-case

condition. The input π fi lter is used to attenuate the refl ected

noise from the regulator input, and is primarily utilized

when the power regulators are closed to the input power

feed to a board, like the input power connectors. If the

regulator design is placed out on the center of the system

board, then the input π fi lter may not be needed because

all of the extra board capacitance and the inductive planes

will provide fi ltering for refl ected emissions. If the system

board has noise sensitive circuitry that is powered from

the same voltage rail as the regulators are, then an input

π fi lter is a good idea to keep regulator noise from cor-

rupting the noise sensitive circuitry on the system board.

Figure 19 shows the CISPR22 B Radiated EMI plots. The

input π fi lter is used to attenuate the refl ected noise from

propagating out onto the input power cables, thus pos-

sibly causing radiated EMI issues. An RC snubber circuit

is optionally used from the SW pin to the PGND pin to

improve the higher frequency attenuation and EMI limit

guard band. A placeholder can accommodate the R

and C

components are probably not necessary, but can be used

or adjusted to improve the radiated limit guard bands at

the higher frequencies by attenuating any switch node

ringing due to parasitic values in the high speed switching

paths. It is important to follow the recommended layout

guidelines and use good X5R or X7R ceramic capacitors

to get good results.

Layout Checklist/Example

The high integration of LTM4618 makes the PC board layout

very simple and easy. However, to optimize its electrical

and thermal performance, some layout considerations

are still necessary.

SNUB

components with 1.2Ω and 470pF . These

SNUB

• Use large PCB copper areas for high current path,

• Test points can be placed on signal pin for monitor-

• Place high frequency ceramic input and output

• Place a dedicated power ground layer underneath the

• To minimize the via conduction loss and reduce mod-

• Do not put vias directly on the pad, unless they are

• Use a separated SGND ground copper area for com-

Figure 20 gives a good example of the recommended

layout.

CNTRL

including V

the PCB conduction loss and thermal stress.

ing during testing.

capacitors next to the V

minimize high frequency noise.

unit.

ule thermal stress, use multiple vias for interconnec-

tion between top layer and other power layers.

capped.

ponents connected to signal pins. Connect the SGND

to PGND underneath the unit.

V

7

6

5

4

3

2

1

IN

Figure 20. Recommended PCB Layout Example

A

B

IN

CNTRL

, PGND and V

C

D

PGND

E

IN

F

, PGND and V

OUT

G

. It helps to minimize

H

J

LTM4618

K

OUT

C

C

OUT

OUT

L

pins to

PGND

M

V

19

OUT

4618 F20

4618fa