GW5BNC15L02 Sharp Microelectronics, GW5BNC15L02 Datasheet - Page 7

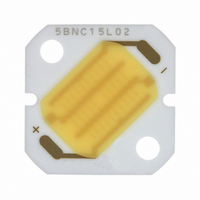

GW5BNC15L02

Manufacturer Part Number

GW5BNC15L02

Description

LED MOD 3.5WATT ZENIGATA 5000K

Manufacturer

Sharp Microelectronics

Type

Without Connectorr

Specifications of GW5BNC15L02

Color

White

Luminous Flux @ Current - Test

190 lm

Current - Test

360mA

Current - Max

360mA

Driver Circuitry

No

Voltage

10.2V

Wavelength

5000K

Configuration

Single

With Connector

No

Voltage - Input

10.2V

Power - Input

3.5W

Illumination Color

White

Wavelength/color Temperature

5000 K

Luminous Flux

190 lm

Power Rating

4.4 W

Operating Voltage

10.2 V

Operating Current

400 mA

Minimum Operating Temperature

- 30 C

Maximum Operating Temperature

+ 90 C

Lens Shape

Rectangular

Number Of Leds

1

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Interface

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

425-2733

GW5BNC15L00

GW5BNC15L00

■ Design Considerations

1. This product is not designed to be electromagnetic- and ionized-particle-radiation resistant.

2. Always use an adequate heatsink with this part, in combination with either (or both) a thermally conductive sheet

3. Do not allow the circuit design to apply any reverse voltage to the LEDs.

4. This module requires a constant-current source for its drive. A constant-voltage supply may provide more than

5. If current in excess of the rated maximum are supplied to this part, hazardous conditions may be created, including

6. If the lead wire to the part comes loose, it could contact the case or heatsink, thereby creating a short circuit and pos-

■ Manufacturing Guidelines

1. Sharp does not recommend cleaning this part, as the silicone resin may be corroded by solvents.

1. Sharp recommends soldering by hand, with a thermally-controlled iron at 380°C; within 10 seconds for each

2. When soldering, do not touch the tip of the iron to the yellow phosphor.

3. This product is not designed for solder reflow or solder flow methods.

4. Do not subject the package to excessive mechanical force during soldering as it may cause deformation or

1. Sharp recommends taking particular notice of the installation method, as the mounting board’s material is alumi-

2. Use screws, adhesives, or both when mounting this device to its heatsink. When using only adhesives, be sure

3. When screw mounting:

Design Guidelines

Cleaning Instructions

Soldering Instructions

Mechanical Installation Instructions

or heat-conducting grease.

the rated current due to lowered V

excess heating, smoke emission, or a possible fire. Take appropriate measures to control excess current and voltage.

sible shock hazard. Take appropriate measures to prevent the lead wire from coming into contact with other parts.

place. Solder on a surface that does not conduct heat.

defects in plated connections. Internal connections may be severed due to mechanical force placed on the pack-

age due to the PCB flexing during the soldering process.

nized ceramic. If incorrectly installed, problems with non-radiation may occur due to cracking of the mounting board.

to check their effectiveness. Use thread locking materials to prevent screws from loosening due to thermal

cycling. If the part is separated from its heatsink, a catastrophic temperature rise may occur, causing self-des-

oldering, device deterioration if not destruction, and smoke emission.

• Refer to Fig. 11 for the recommended dimensions.

• Screw torque: within 0.2 N•m.

• Use thread locking materials.

• Use materials with low galvanic action, such as stainless steel.

• Do not use flathead screws, which can cause substrate cracks due to stress at the screw holes.

• Do not install the part into a board which is warped in a convex direction. This part can be easily damaged by

• To maximize thermal efficiency between the device and its heatsink, Sharp recommends a thermally-conduc-

• Circuit board cracks can be caused when screws are tightened; be sure to check the actual conditions carefully.

torquing it to a convexedly-warped mounting surface.

tive sheet and conductive grease.

F

created caused by part heating.

7

GW5xxC15Lx2

Sheet No.: DG-xxxxx