ATF-541M4-BLK Avago Technologies US Inc., ATF-541M4-BLK Datasheet - Page 11

ATF-541M4-BLK

Manufacturer Part Number

ATF-541M4-BLK

Description

IC ENHANCED MOD SUDIOMORPHIC HEM

Manufacturer

Avago Technologies US Inc.

Datasheet

1.ATF-541M4-BLK.pdf

(16 pages)

Specifications of ATF-541M4-BLK

Gain

17.5dB

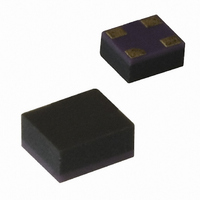

Package / Case

4-MiniPak (1412)

Current Rating

120mA

Power - Output

21.4dBm

Frequency

2GHz

Transistor Type

pHEMT FET

Noise Figure

0.5dB

Current - Test

60mA

Voltage - Test

3V

Drain Source Voltage Vds

3V

Continuous Drain Current Id

120mA

Power Dissipation Pd

360mW

Noise Figure Typ

0.5dB

Rf Transistor Case

MiniPak

No. Of Pins

4

Frequency Max

10GHz

Drain Current Idss Max

60mA

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

Q2380948

11

Electrostatic Sensitivity

FETs and RFICs are electrostatic dis‑

charge (ESD) sensitive devices. Avago

devices are manufactured using

a very robust and reliable PHEMT

process, however, permanent dam‑

age may occur to these devices if

they are subjected to high‑energy

electrostatic discharges. Electrostatic

charges as high as several thousand

volts (which readily accumulate on the

human body and on test equipment)

can discharge without detection and

may result in failure or degradation in

performance and reliability.

Figure 21. Leaded Solder Reflow Profile.

Figure 22. Lead-free Solder Reflow Profile.

350

300

250

221

200

150

100

250

200

150

100

50

50

0

0

0

0

30

60

Preheat 130 –170 C

60

Max. 150s

Min. 60s

90

Preheat

Zone

120

150

120

TIME (seconds)

TIME (seconds)

180

Electronic devices may be subjected

to ESD damage in any of the follow‑

ing areas:

• Storage & handling

• Inspection

• Assembly & testing

• In‑circuit use

The ATF‑541M4 is an ESD Class 1

device. Therefore, proper ESD pre‑

cautions are recommended when

handling, inspecting, testing, and

assembling these devices to avoid

damage.

Reflow

Zone

210

180

240

Cool Down

Zone

Peak Temperature

270

Max. 255 C

Min. 240 C

Reflow Time

Max. 90s

Min. 60s

240

300

T

MAX

330

360

300

Any user‑accessible points in wireless

equipment (e.g. antenna or battery

terminals) provide an opportunity for

ESD damage.

For circuit applications in which the

ATF‑541M4 is used as an input or

output stage with close coupling

to an external antenna, the device

should be protected from high volt‑

age spikes due to human contact with

the antenna. A good practice, illus‑

trated in Figure 23, is to place a shunt

inductor or RF choke at the antenna

connection to protect the receiver

and transmitter circuits. It is often ad‑

vantageous to integrate the RF choke

into the design of the diplexer or T/R

switch control circuitry.

Figure 23. In-circuit ESD Protection.