P7S-14F Omron, P7S-14F Datasheet - Page 17

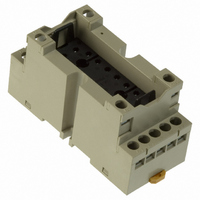

P7S-14F

Manufacturer Part Number

P7S-14F

Description

Contact OSTI

Manufacturer

Omron

Series

G7Sr

Type

Socketr

Specifications of P7S-14F

Number Of Positions

14

Mounting Type

DIN Rail

Termination Style

Screw Terminal

Socket Mounting

DIN Rail

Socket Terminals

Screw

Voltage Rating

24VDC

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

G7S Series

For Use With

Z2362 - RELAY SAFETY 6A 24VDC PLUG-INZ2363 - RELAY SAFETY 6A 24VDC PLUG-IN

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

P7S14F

Z2417

Z2417

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

P7S-14F

Manufacturer:

Omron Electronics Inc-EMC Div

Quantity:

135

B Noise from Contacts

Noise may be transmitted to the electronic circuit when switching a

load, such as a motor or transistor, that generates a surge at the

contacts. When designing patterns, take the following three points

into consideration.

1. Do not place a signal transmission pattern near the contact

2. Shorten the length of patterns that may be sources of noise.

3. Block noise from electronic circuits by means such as

C High-frequency Patterns

As the manipulated frequency is increased, pattern mutual

interference also increases. Therefore, take noise countermeasures

into consideration when designing high-frequency pattern and land

shapes.

G-6 Shape of Lands

1. The land section should be on the center line of the copper-foil

2. A break in the circular land area will prevent molten solder from

G-7 Pattern Conductor Width and Thickness

The following thicknesses of copper foil are standard: 35 μm and

70 μm. The conductor width is determined by the current flow and

allowable temperature rise. Refer to the chart below as a simple

guideline.

Conductor Width and Permissible Current

(According to IEC Pub326-3)

Correct Examples

Incorrect

Examples

pattern.

constructing ground patterns.

pattern, so that the soldered fillets become uniform.

filling holes reserved for components which must be soldered

manually after the automatic soldering of the PCB is complete.

0.5

50

30

20

10

7

5

3

2

7

5

3

2

1

http://www.ia.omron.com/

Cross-sectional area (mm

0.03 0.05 0.07 0.1

0.2 to 0.5 mm

305 /m

35 μm

2

)

Break in land

0.3

610 /m

70 μm

2

0.5 0.7 1

100˚C

75˚C

50˚C

40˚C

30˚C

20˚C

10˚C

2

G-8 Conductor Pitch

The conductor pitch on a PCB is determined by the insulation

characteristics between conductors and the environmental

conditions under which the PCB is to be used. Refer to the following

graph. If the PCB must conform to safety organization standards

(such as UL, CSA, or IEC), however, priority must be given to

fulfilling their requirements. Also, multi-layer PCBs can be used as a

means of increasing the conductor pitch.

Voltage between Conductors vs. Conductor Pitch

(According to IEC Pub326-3)

G-9 Securing the PCB

Although the PCB itself is not normally a source of vibration or shock,

it may prolong vibration or shock by resonating with external vibration

or shock. Securely fix the PCB, paying attention to the following

points.

Rack mounting

Screw mounting

Mounting method

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

3,000

2,000

1,000

700

500

300

200

100

A = Without coating at altitude of 3,000 m max.

B = Without coating at altitude of 3,000 m or higher but lower than 15,000 m

C = With coating at altitude of 3,000 m max.

D = With coating at altitude of 3,000 m or higher

70

50

30

20

0.1

0.2 0.3 0.5 0.7 1.0

No gap between rack's guide and PCB

• Securely tighten screw.

• Attach rubber washers to screws when

Place heavy components such as Relays on

part of PCB near where screws are to be

used.

mounting components that are affected by

shock (such as audio devices.)

2

Conductor pitch (mm)

3

5

Process

10

D

C

A

B

C-12