P7S-14F Omron, P7S-14F Datasheet - Page 14

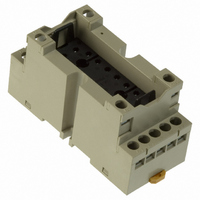

P7S-14F

Manufacturer Part Number

P7S-14F

Description

Contact OSTI

Manufacturer

Omron

Series

G7Sr

Type

Socketr

Specifications of P7S-14F

Number Of Positions

14

Mounting Type

DIN Rail

Termination Style

Screw Terminal

Socket Mounting

DIN Rail

Socket Terminals

Screw

Voltage Rating

24VDC

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

G7S Series

For Use With

Z2362 - RELAY SAFETY 6A 24VDC PLUG-INZ2363 - RELAY SAFETY 6A 24VDC PLUG-IN

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

P7S14F

Z2417

Z2417

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

P7S-14F

Manufacturer:

Omron Electronics Inc-EMC Div

Quantity:

135

C-B-11 Using DC-operated Relays

For a DC-operated Relay power supply, use a power supply with a

maximum ripple percentage of 5%. An increase in the ripple

percentage will cause humming.

C-B-12 Using DC-operated Relays

To make the correct connections, first check the individual terminal

numbers and applied power supply polarities provided in this catalog.

If the polarity is connected in reverse for the coil power supply when

Relays with surge suppressor diodes or Relays with operation

indicators are used, it can cause problems such as Relay

malfunctioning, damage to diodes, or failure of indicators. Also, for

Relays with diodes, it can cause damage to devices in the circuit due

to short-circuiting.

Polarized Relays that use a permanent magnet in a magnetic circuit

will not operate if the power supply to the coil is connected in reverse.

C-B-13 Using DC-operated Relays

If insufficient voltage is applied to the coil, either the Relay will not

operate or operation will be unstable. This will cause problems such

as a drop in the electrical durability of the contacts and contact

welding.

In particular, when a load with a large surge current, such as a large

motor, is used, the voltage applied to the coil may drop when a large

inrush current occurs to operate the load as the power is turned ON.

Also, if a Relay is operated while the voltage is insufficient, it will

cause the Relay to malfunction even at vibration and shock values

below the specifications specified in the specification sheets and this

catalog. Therefore, be sure to apply the rated voltage to the coil.

C Mounting Design

C-C-1 Lead Wire Diameters

Lead wire diameters are determined by the size of the load current.

As a standard, use lead wires at least the size of the cross-sectional

areas shown in the following table. If the lead wire is too thin, it may

cause burning due to abnormal heating of the wire.

C-C-2 When Sockets are Used

Check Relay and socket ratings, and use devices at the lower end of

the ratings. Relay and socket rated values may vary, and using

devices at the high end of the ratings can result in abnormal heating

and burning at connections.

6

10

15

20

Ripple percentage %=

Permissible current (A)

(1) Input Power Supply Ripple

(2) Coil Polarity

(3) Coil Voltage Insufficiency

Emax−Emin

Emin

Emean

http://www.ia.omron.com/

Emax

× 100%

Emean

Smoothing

capacitor

E max.= Maximum value of ripple component

E min.= Minimum value of ripple component

E mean= Mean value of DC component

0.75

1.25

2

3.5

Ripple component

Cross-sectional area (mm

DC component

Relay

2

)

C-C-3 Mounting Direction

Depending on the model, a particular mounting direction may be

specified. Check this catalog and then mount the device in the

correct direction.

C-C-4 When Devices Such as Microcomputers are in

If a device that is susceptible to external noise, such as a

microcomputer, is located nearby, take noise countermeasures into

consideration when designing the pattern and circuits. If Relays are

driven using a device such as a microcomputer, and a large current

is switched by Relay contacts, noise generated by arcing can cause

the microcomputer to malfunction.

D Operating and Storage

D-1 Operating, Storage, and Transport

During operation, storage, and transport, avoid direct sunlight and

maintain room temperature, humidity, and pressure.

• If Relays are used or stored for a long period of time in an

• If the ambient temperature is suddenly changed in an atmosphere

• If Relays are to be used after having been stored for a long period,

D-2 Operating Atmosphere

• Do not use Relays in an atmosphere containing flammable or

• Do not use Relays in an atmosphere containing dust. The dust will

D-3 Using Relays in an Atmosphere Containing

Do not use Relays in a location where silicon gas, sulfuric gas (SO

or H

If Relays are stored or used for a long period of time in an

atmosphere of sulfuric gas or organic gas, contact surfaces may

become corroded and cause contact instability and obstruction, and

terminal soldering characteristics may be degraded.

Also, if Relays are stored or used for a long period of time in an

atmosphere of silicon gas, a silicon film will form on contact surfaces,

causing contact failure.

The effects of corrosive gas can be reduced by the processing

shown in the following table.

Outer case, housing

PCB, copper plating

Connectors

atmosphere of high temperature and humidity, oxidation and

sulphurization films will form on contact surfaces, causing problems

such as contact failure.

of high temperature and humidity, condensation will develop inside

of the Relay. This condensation may cause insulation failure and

deterioration of insulation due to tracking (an electric phenomenon)

on the surface of the insulation material.

Also, in an atmosphere of high humidity, with load switching

accompanied by a comparatively large arc discharge, a dark green

corrosive product may be generated inside of the Relay. To prevent

this, it is recommended that Relays be used in at low humidity.

first inspect the power transmission before use. Even if Relays are

stored without being used at all, contact instability and obstruction

may occur due to factors such as chemical changes to contact

surfaces, and terminal soldering characteristics may be degraded.

explosive gas. Arcs and heating resulting from Relay switching may

cause fire or explosion.

get inside the Relays and cause contact failure.

2

Environments

S), or organic gas is present.

Corrosive Gas (Silicon, Sulfuric, or Organic Gas)

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Proximity

Item

Seal structure using packing.

Apply coating.

Apply gold plating or rhodium

plating.

Processing

2

C-9