HFBR-0564 Avago Technologies US Inc., HFBR-0564 Datasheet - Page 11

HFBR-0564

Manufacturer Part Number

HFBR-0564

Description

Fiber Optics, Evaluation Kit

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HFBR-0562.pdf

(14 pages)

Specifications of HFBR-0564

Silicon Manufacturer

Avago

Silicon Core Number

HFBR-591xE

Kit Application Type

Communication & Networking

Application Sub Type

MT-RJ Gigabit Ethernet Transceiver

Main Purpose

Interface, Ethernet

Embedded

No

Utilized Ic / Part

HFCT-591xE, HFBR-591xE

Primary Attributes

MT-RJ Gigabit, Multimode and Singlemode Applications

Secondary Attributes

MT-RJ Fiber Connector Interface

Operating Voltage

3.3 V

Description/function

Fiber Optic Kit

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

HFBR-591x, HFCT-591

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

11

Figure 11. HFBR-591xE open air radiation

Figure 12. HFBR-591xE simulated chassis radiation

Handling

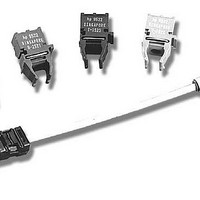

Process Plug

The HFBR-591xE and HFCT-591xE

SFF transceivers are supplied with a

process plug for protection of optical

ports. This process plug prevents

contamination during solder and

aqueous rinse as well as during

handling, shipping or storage. It is

made of high temperature, moulded

material containing an insert that

forms a seal around the optical port.

The multimode (black) and single

mode process plugs (blue) are not

inter changeable. The process plug is

capable of withstanding +80° C and

a rinse pressure of 110 psi.

Optical Path Cleanliness

To ensure optimum product per-

formance, the optical light path

must not be obscured by any con-

tamination. The following cleaning

procedure is suggested:

1) Use a nitrogen air gun, or similar,

2) Use a nitrogen air gun, or similar,

to blow clean the MT ferrule inside

the housing each time before

inserting the MT-RJ patchcord.

to blow clean the MT ferrule in

the MT-RJ patchcord each time

before mating with the module

or another patchcord.

3) Wipe the ferrule gently with IPA

4) Use a nitrogen air gun, or similar,

5) Put modules and patchcords

6) Use the modules process plug

Recommended Solder Fluxes and

Cleaning/Degreasing Chemicals

Solder fluxes used with the SFF

fiber optic transceiver should be

water-soluble, organic solder fluxes.

Some recommended solder fluxes

are Lonco 3355-11 from London

Chemical West, Inc. of Burbank, CA

and 100 Flux from Alpha metals of

Jersey City, NJ.

Recommended cleaning and de-

greasing chemicals for the SFF are

alcohol’s (methyl, isopropyl, isobutyl)

and aliphates (hexane, heptane).

Do not use partially halogenated

hydrocarbons for cleaning/degreas-

ing. Examples of chemicals to avoid

are 1.1.1 trichloroethane, ketones

(such as MEK), acetate, chloroform,

ethyl acetate, methylene dichloride,

phenaol, methylene chloride or N-

methylpyrolldone.

Thermal Analysis/Considerations

The HFCT-591xE single mode SFF

transceiver consumes a typical 600

mW of power. The case temperature

is approximately +5° C higher than

ambient temperature and the metal

shield of the transceiver enables

efficient power dissipation.

using lint free material no less

than once every 25 matings.

to blow clean the ferrule each

time after wiping the ferrule with

HFE 7100 to ensure that no debris

is left on the MT endface.

on a dry and clean surface

after

contamination.

and the patchcords dust cap

whenever they are not in use.

demating

to

avoid