GCM1555C1H221JA16D Murata, GCM1555C1H221JA16D Datasheet - Page 48

GCM1555C1H221JA16D

Manufacturer Part Number

GCM1555C1H221JA16D

Description

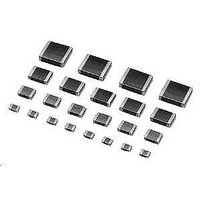

Multilayer Ceramic Capacitors (MLCC) - SMD/SMT 0402 220pF 50volts C0G +/-5%

Manufacturer

Murata

Series

GCMr

Datasheets

1.GCM188R71C105KA64D.pdf

(50 pages)

2.GCM1555C1H221JA16D.pdf

(2 pages)

3.GCM1555C1H221JA16D.pdf

(1 pages)

Specifications of GCM1555C1H221JA16D

Voltage Rating

50 Volts

Operating Temperature Range

- 55 C to + 125 C

Temperature Coefficient / Code

C0G (NP0)

Product

Automotive MLCCs

Dimensions

0.5 mm W x 1 mm L x 0.5 mm H

Dissipation Factor Df

0.01

Termination Style

SMD/SMT

Capacitance

220 pF

Tolerance

5 %

Package / Case

0402 (1005 metric)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

GCM1555C1H221JA16D

Manufacturer:

MURATA

Quantity:

640 000

2

!Note

• This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’s specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

• This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

sales representatives or product engineers before ordering.

4. Cleaning

5. Resin Coating

!Note

46

Notice

Please confirm there is no problem in the reliability of the

product beforehand when cleaning it with the intended

equipment.

The residue after cleaning it might cause the decrease in

the surface resistance of the chip and the corrosion of the

electrode part, etc. As a result it might cause reliability to

deteriorate. Please confirm beforehand that there is no

problem with the intended equipment in ultrasonic

cleansing.

Please use it after confirming there is no influence on the

product with a intended equipment beforehand when the

resin coating and molding.

A cracked chip might be caused at the cooling/heating

cycle by the amount of resin spreading and/or bias

thickness.

The resin for coating and molding must be selected as

the stress is small when stiffening and the hygroscopic is

low as possible.

Continued from the preceding page.

• Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C03E.pdf

09.3.31