GCM1555C1H221JA16D Murata, GCM1555C1H221JA16D Datasheet - Page 24

GCM1555C1H221JA16D

Manufacturer Part Number

GCM1555C1H221JA16D

Description

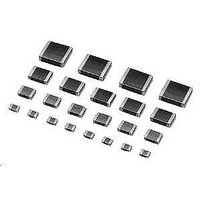

Multilayer Ceramic Capacitors (MLCC) - SMD/SMT 0402 220pF 50volts C0G +/-5%

Manufacturer

Murata

Series

GCMr

Datasheets

1.GCM188R71C105KA64D.pdf

(50 pages)

2.GCM1555C1H221JA16D.pdf

(2 pages)

3.GCM1555C1H221JA16D.pdf

(1 pages)

Specifications of GCM1555C1H221JA16D

Voltage Rating

50 Volts

Operating Temperature Range

- 55 C to + 125 C

Temperature Coefficient / Code

C0G (NP0)

Product

Automotive MLCCs

Dimensions

0.5 mm W x 1 mm L x 0.5 mm H

Dissipation Factor Df

0.01

Termination Style

SMD/SMT

Capacitance

220 pF

Tolerance

5 %

Package / Case

0402 (1005 metric)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

GCM1555C1H221JA16D

Manufacturer:

MURATA

Quantity:

640 000

1

!Note

• This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’s specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

• This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

sales representatives or product engineers before ordering.

!Note

1. Mounting Position

2. Chip Placing

22

!Caution

!Caution

!Caution (Soldering and Mounting)

An excessively low bottom dead point of the suction

Dirt particles and dust accumulated between the suction

Choose a mounting position that minimizes the stress

imposed on the chip during flexing or bending of the

board.

nozzle imposes great force on the chip during mounting,

causing cracked chips. So adjust the suction nozzle's

bottom dead point by correcting warp in the board.

Normally, the suction bottom dead point must be set on

the upper surface of the board. Nozzle pressure for chip

mounting must be a 1 to 3N static load.

nozzle and the cylinder inner wall prevent the nozzle from

moving smoothly. This imposes great force on the chip

during mounting, causing cracked chips. And the locating

claw, when worn out, imposes uneven forces on the chip

when positioning, causing cracked chips. The suction

nozzle and the locating claw must be maintained,

checked and replaced periodically.

• Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

[Component direction]

[Chip Mounting Close to Board Separation Point]

[Incorrect]

[Correct]

Perforation

Suction Nozzle

A

Board

Slit

B

Support Pin

D

C

Deflection

Continued on the following page.

Locate chip

horizontal to the

direction in which

stress acts.

Chip arrangement

Worst A-C- (B, D)

Best

Board Guide

C03E.pdf

09.3.31