GCM1555C1H221JA16D Murata, GCM1555C1H221JA16D Datasheet - Page 45

GCM1555C1H221JA16D

Manufacturer Part Number

GCM1555C1H221JA16D

Description

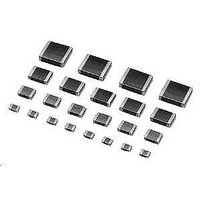

Multilayer Ceramic Capacitors (MLCC) - SMD/SMT 0402 220pF 50volts C0G +/-5%

Manufacturer

Murata

Series

GCMr

Datasheets

1.GCM188R71C105KA64D.pdf

(50 pages)

2.GCM1555C1H221JA16D.pdf

(2 pages)

3.GCM1555C1H221JA16D.pdf

(1 pages)

Specifications of GCM1555C1H221JA16D

Voltage Rating

50 Volts

Operating Temperature Range

- 55 C to + 125 C

Temperature Coefficient / Code

C0G (NP0)

Product

Automotive MLCCs

Dimensions

0.5 mm W x 1 mm L x 0.5 mm H

Dissipation Factor Df

0.01

Termination Style

SMD/SMT

Capacitance

220 pF

Tolerance

5 %

Package / Case

0402 (1005 metric)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

GCM1555C1H221JA16D

Manufacturer:

MURATA

Quantity:

640 000

!Note

• This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’s specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

• This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

sales representatives or product engineers before ordering.

!Note

6. Correction with a Soldering Iron

Table 3

7. Washing

FAILURE TO FOLLOW THE ABOVE CAUTIONS MAY

RESULT, WORST CASE, IN A SHORT CIRCUIT AND

FUMING WHEN THE PRODUCT IS USED.

G--21/31

G--32

*Applicable for both Pb-Sn and Lead Free Solder.

Part Number

Pb-Sn Solder: Sn-37Pb

Lead Free Solder: Sn-3.0Ag-0.5Cu

Optimum Solder Amount when re-working Using a

When sudden heat is applied to the components by use

of a soldering iron, the mechanical strength of the

components will go down because the extreme

temperature change causes deformations inside the

components.

In order to prevent mechanical damage to the

components, preheating is required for both the

components and the PCB board.

Preheating conditions, (The "Temperature of the

Soldering Iron tip", "Preheating Temperature",

"Temperature Differential" between iron tip and the

Soldering Iron

In case of larger sizes than Gpp21, the top of the solder

fillet should be lower than 2/3's of the thickness of the

component.

If the solder amount is excessive, the risk of cracking is

higher during board bending or under any other stressful

conditions.

A Soldering iron ø3mm or smaller should be used.

It is also necessary to keep the soldering iron from

touching the components during the re-work.

Solder wire with ø0.5mm or smaller is required for

soldering.

Excessive output of ultrasonic oscillation during cleaning

causes PCBs to resonate, resulting in cracked chips or

broken solder. Take note not to vibrate PCBs.

Continued from the preceding page.

• Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Temperature

of Soldering

350 C max.

280 C max.

Iron tip

Temperature

150 C min.

150 C min.

Preheating

Temperature

Differential

TV190D

TV130D

( T)

Atmosphere

air

air

components and the PCB), should be within the

conditions of table 3.

It is required to keep the temperature differential between

the soldering Iron and the components surface ( T) as

small as possible.

After soldering, do not allow the component/PCB to cool

down rapidly.

The operating time for the re-working should be as short

as possible. When re-working time is too long, it may

cause solder leaching, and that will cause a reduction of

the adhesive strength of the terminations.

Solder Amount

!Caution

in section

C03E.pdf

43

09.3.31

2