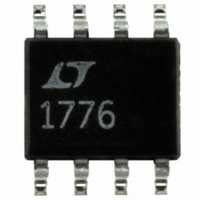

LT1776CS8#TR Linear Technology, LT1776CS8#TR Datasheet - Page 9

LT1776CS8#TR

Manufacturer Part Number

LT1776CS8#TR

Description

IC REG SW STEPDOWN HI EFF 8SOIC

Manufacturer

Linear Technology

Type

Step-Down (Buck)r

Datasheet

1.LT1776CS8PBF.pdf

(20 pages)

Specifications of LT1776CS8#TR

Internal Switch(s)

Yes

Synchronous Rectifier

No

Number Of Outputs

1

Voltage - Output

1.24 ~ 34 V

Current - Output

700mA

Frequency - Switching

200kHz

Voltage - Input

7.4 ~ 40 V

Operating Temperature

0°C ~ 125°C

Mounting Type

Surface Mount

Package / Case

8-SOIC (3.9mm Width)

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Power - Output

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

APPLICATIONS

limits the inductor’s current carrying capability as the I

power threatens to overheat the inductor. If applicable,

remember to include the condition of output short circuit.

Although the peak current rating of the inductor can be

exceeded in short-circuit operation, as core saturation per

se is not destructive to the core, excess resistive self-

heating is still a potential problem.

The final inductor selection is generally based on cost,

which usually translates into choosing the smallest physi-

cal size part that meets the desired inductance value,

resistance and current carrying capability. An additional

factor to consider is that of physical construction. Briefly

stated, “open” inductors built on a rod- or barrel-shaped

core generally offer the smallest physical size and lowest

cost. However their open construction does not contain

the resulting magnetic field, and they may not be accept-

able in RFI-sensitive applications. Toroidal style induc-

tors, many available in surface mount configuration, offer

improved RFI performance, generally at an increase in

cost and physical size. And although custom design is

always a possibility, most potential LT1776 applications

can be handled by the array of standard, off-the-shelf

inductor products offered by the major suppliers.

Selecting Freewheeling Diode

Highest efficiency operation requires the use of a Schottky

type diode. DC switching losses are minimized due to its

low forward voltage drop, and AC behavior is benign due

to its lack of a significant reverse recovery time. Schottky

diodes are generally available with reverse voltage ratings

of 60V and even 100V, and are price competitive with other

types.

The use of so-called “ultrafast” recovery diodes is gener-

ally not recommended. When operating in continuous

mode, the reverse recovery time exhibited by “ultrafast”

diodes will result in a slingshot type effect. The power

internal switch will ramp up V

attempt to get it to recover. Then, when the diode has

finally turned off, some tens of nanoseconds later, the V

node voltage ramps up at an extremely high dV/dt, per-

haps 5 to even 10V/ns ! With real world lead inductances,

the V

SW

node can easily overshoot the V

U

INFORMATION

U

IN

current into the diode in an

W

IN

rail. This can

U

SW

2

R

result in poor RFI behavior and if the overshoot is severe

enough, damage the IC itself.

Selecting Bypass Capacitors

The basic topology as shown in Figure 1 uses two bypass

capacitors, one for the V

V

User selection of an appropriate output capacitor is rela-

tively easy, as this capacitor sees only the AC ripple current

in the inductor. As the LT1776 is designed for buck or

step-down applications, output voltage will nearly always

be compatible with tantalum type capacitors, which are

generally available in ratings up to 35V or so. These

tantalum types offer good volumetric efficiency and many

are available with specified ESR performance. The product

of inductor AC ripple current and output capacitor ESR will

manifest itself as peak-to-peak voltage ripple on the output

node. (Note: If this ripple becomes too large, heavier

control loop compensation, at least at the switching fre-

quency, may be required on the V

manding applications, requiring very low output ripple,

may be best served not with a single extremely large

output capacitor, but instead by the common technique of

a separate L/C lowpass post filter in series with the output.

(In this case, “Two caps are better than one”.)

The input bypass capacitor is normally a more difficult

choice. In a typical application e.g., 40V

relatively heavy V

for only a small portion of the oscillator period (low ON

duty cycle). The resulting RMS ripple current, for which

the capacitor must be rated, is often several times the DC

average V

supply as the power switch turns on and off will be related

to the product of capacitor ESR, and the relatively high

instantaneous current drawn by the switch. To compound

these problems is the fact that most of these applications

will be designed for a relatively high input voltage, for

which tantalum capacitors are generally unavailable. Rela-

tively bulky “high frequency” aluminum electrolytic types,

specifically constructed and rated for switching supply

applications, may be the only choice.

OUT

output supply.

IN

current. Similarly, the “glitch” seen on the V

IN

current is drawn by the power switch

IN

input supply and one for the

C

pin.) The most de-

IN

LT1776

to 5V

OUT

9

IN

,