LM3410XSD/NOPB National Semiconductor, LM3410XSD/NOPB Datasheet - Page 10

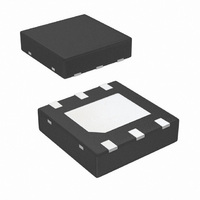

LM3410XSD/NOPB

Manufacturer Part Number

LM3410XSD/NOPB

Description

IC LED DRVR WT/OLED BCKLGT 6-LLP

Manufacturer

National Semiconductor

Series

PowerWise®r

Type

Backlight, OLED, White LEDr

Datasheet

1.LM3410XMFNOPB.pdf

(32 pages)

Specifications of LM3410XSD/NOPB

Constant Current

Yes

Topology

PWM, SEPIC, Step-Up (Boost)

Number Of Outputs

1

Internal Driver

Yes

Type - Primary

Automotive, Backlight, Flash/Torch

Type - Secondary

High Brightness LED (HBLED), OLED, White LED

Frequency

1.2MHz ~ 2MHz

Voltage - Supply

2.7 V ~ 5.5 V

Voltage - Output

3 V ~ 24 V

Mounting Type

Surface Mount

Package / Case

6-LLP

Operating Temperature

-40°C ~ 125°C

Current - Output / Channel

2.8A

Internal Switch(s)

Yes

Efficiency

88%

For Use With

LM3410XSDLEDEV - BOARD EVAL LM3410 BOOST LLP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

LM3410XSDTR

www.national.com

age and the operating temperature. The ESL of an input

capacitor is usually determined by the effective cross sec-

tional area of the current path. At the operating frequencies

of the LM3410, certain capacitors may have an ESL so large

that the resulting impedance (2

required to provide stable operation. As a result, surface

mount capacitors are strongly recommended. Multilayer ce-

ramic capacitors (MLCC) are good choices for both input and

output capacitors and have very low ESL. For MLCCs it is

recommended to use X7R or X5R dielectrics. Consult capac-

itor manufacturer datasheet to see how rated capacitance

varies over operating conditions.

OUTPUT CAPACITOR

The LM3410 operates at frequencies allowing the use of ce-

ramic output capacitors without compromising transient re-

sponse. Ceramic capacitors allow higher inductor ripple

without significantly increasing output ripple. The output ca-

pacitor is selected based upon the desired output ripple and

transient response. The initial current of a load transient is

provided mainly by the output capacitor. The output

impedance will therefore determine the maximum voltage

perturbation. The output ripple of the converter is a function

of the capacitor’s reactance and its equivalent series resis-

tance (ESR):

When using MLCCs, the ESR is typically so low that the ca-

pacitive ripple may dominate. When this occurs, the output

ripple will be approximately sinusoidal and 90° phase shifted

from the switching action.

Given the availability and quality of MLCCs and the expected

output voltage of designs using the LM3410, there is really no

need to review any other capacitor technologies. Another

benefit of ceramic capacitors is their ability to bypass high

frequency noise. A certain amount of switching edge noise

will couple through parasitic capacitances in the inductor to

the output. A ceramic capacitor will bypass this noise while a

tantalum will not. Since the output capacitor is one of the two

external components that control the stability of the regulator

control loop, most applications will require a minimum at 0.47

µF of output capacitance. Like the input capacitor, recom-

mended multilayer ceramic capacitors are X7R or X5R.

Again, verify actual capacitance at the desired operating volt-

age and temperature.

DIODE

The diode (D1) conducts during the switch off time. A Schottky

diode is recommended for its fast switching times and low

forward voltage drop. The diode should be chosen so that its

current rating is greater than:

The reverse breakdown rating of the diode must be at least

the maximum output voltage plus appropriate margin.

OUTPUT OVER-VOLTAGE PROTECTION

A simple circuit consisting of an external zener diode can be

implemented to protect the output and the LM3410 device

from an over-voltage fault condition. If an LED fails open, or

is connected backwards, an output open circuit condition will

occur. No current is conducted through the LED’s, and the

feedback node will equal zero volts. The LM3410 will react to

I

D1

≥

I

OUT

π

fL) will be higher than that

10

this fault by increasing the duty-cycle, thinking the LED cur-

rent has dropped. A simple circuit that protects the LM3410

is shown in figure 6.

Zener diode D2 and resistor R3 is placed from V

with the string of LEDs. If the output voltage exceeds the

breakdown voltage of the zener diode, current is drawn

through the zener diode, R3 and sense resistor R1. Once the

voltage across R1 and R3 equals the feedback voltage of

190mV, the LM3410 will limit its duty-cycle. No damage will

occur to the LM3410, the LED’s, or the zener diode. Once the

fault is corrected, the application will work as intended.

PCB Layout Considerations

When planning layout there are a few things to consider when

trying to achieve a clean, regulated output. The most impor-

tant consideration when completing a Boost Converter layout

is the close coupling of the GND connections of the C

pacitor and the LM3410 PGND pin. The GND ends should be

close to one another and be connected to the GND plane with

at least two through-holes. There should be a continuous

ground plane on the bottom layer of a two-layer board except

under the switching node island. The FB pin is a high

impedance node and care should be taken to make the FB

trace short to avoid noise pickup and inaccurate regulation.

The R

possible to the IC, with the AGND of R

as possible to the AGND (pin 5 for the LLP) of the IC. Radiated

noise can be decreased by choosing a shielded inductor. The

remaining components should also be placed as close as

possible to the IC. Please see Application Note AN-1229 for

further considerations and the LM3410 demo board as an ex-

ample of a four-layer layout.

Below is an example of a good thermal & electrical PCB de-

sign.

SET

FIGURE 6. Overvoltage Protection Circuit

feedback resistor should be placed as close as

SET

(R1) placed as close

30038530

OUT

in parallel

OUT

ca-