53892-7 TE Connectivity, 53892-7 Datasheet - Page 4

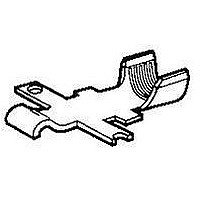

53892-7

Manufacturer Part Number

53892-7

Description

Power to the Board CONTACT CRIMP 18-12 Series 1

Manufacturer

TE Connectivity

Series

Series Ir

Specifications of 53892-7

Product Type

Contacts

Termination Style

Crimp

Contact Plating

Gold (30)

Contact Material

Copper

Wire Gauge Range

18-12

Wire Size (awg)

18-12

Termination Method To Wire/cable

Crimp

Ul File Number

E28476

Csa File Number

LR7189

Wire/cable Type

Discrete Wire

Make First / Break Last

No

Contact - Rated Current (a)

31

Operating Voltage Reference

AC

Operating Voltage (vac)

600

Wire/cable Size (awg)

12 – 18

Wire/cable Size (mm²)

0.811 – 3.09

Wire/cable Size (cma)

1,601 – 6,098

Profile Height (y-axis) (mm [in])

3.05 [0.120]

Length (x-axis) (mm [in])

18.29 [0.720]

Width (z-axis) (mm [in])

3.76 [0.148]

Underplate Material Thickness (µm [?in])

1.27 [50.000]

Contact Type

Pin/Socket

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Contact Base Material

Copper

Contact Design

Spring Latch

Underplate Material

Nickel

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Vde Tested

No

Agency/standard

UL, CSA

Ul Rating

Recognized

Csa Certified

Yes

Operating Temperature (°c [°f])

-40 – +75 [-40 – +167]

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

0.864 – 0.914 [0.034 – 0.036]

Accepts Wire Material

Copper

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Loose Piece

Lead Free Status / Rohs Status

Details

3.6.

Rev B

Product Qualification and Requalification Test Sequence

NOTE

(a)

(b)

(c)

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Discontinuities shall not be measured. Energize at 18°C level for 100% loadings per Test

Specification 109-151.

Exam ination of product

Term ination resistance

Insulation resistance

Dielectric withstanding voltage

Tem perature rise vs current

Solderability

Crim p tensile

Vibration

Physical shock

Contact retention

Durability

Mating force

Unm ating force

Therm al shock

Hum idity-tem perature cycling

Tem perature life

Mixed flowing gas

Test or Exam ination

Figure 2

1,10

3,7

11

5

6

9

4

2

8

1

Test Sequence (b)

Test Group (a)

6(c)

1,9

2,7

3,8

2

5

4

3,7

1,8

2,6

3

4

5

1,3

2

4

108-11026

4 of 9