53892-7 TE Connectivity, 53892-7 Datasheet - Page 2

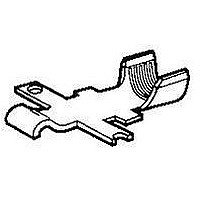

53892-7

Manufacturer Part Number

53892-7

Description

Power to the Board CONTACT CRIMP 18-12 Series 1

Manufacturer

TE Connectivity

Series

Series Ir

Specifications of 53892-7

Product Type

Contacts

Termination Style

Crimp

Contact Plating

Gold (30)

Contact Material

Copper

Wire Gauge Range

18-12

Wire Size (awg)

18-12

Termination Method To Wire/cable

Crimp

Ul File Number

E28476

Csa File Number

LR7189

Wire/cable Type

Discrete Wire

Make First / Break Last

No

Contact - Rated Current (a)

31

Operating Voltage Reference

AC

Operating Voltage (vac)

600

Wire/cable Size (awg)

12 – 18

Wire/cable Size (mm²)

0.811 – 3.09

Wire/cable Size (cma)

1,601 – 6,098

Profile Height (y-axis) (mm [in])

3.05 [0.120]

Length (x-axis) (mm [in])

18.29 [0.720]

Width (z-axis) (mm [in])

3.76 [0.148]

Underplate Material Thickness (µm [?in])

1.27 [50.000]

Contact Type

Pin/Socket

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Contact Base Material

Copper

Contact Design

Spring Latch

Underplate Material

Nickel

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Vde Tested

No

Agency/standard

UL, CSA

Ul Rating

Recognized

Csa Certified

Yes

Operating Temperature (°c [°f])

-40 – +75 [-40 – +167]

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

0.864 – 0.914 [0.034 – 0.036]

Accepts Wire Material

Copper

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Loose Piece

Lead Free Status / Rohs Status

Details

3.4.

3.5.

Rev B

Exam ination of product.

Term ination resistance.

Insulation resistance.

Dielectric withstanding voltage.

Tem perature rise vs current.

Solderability.

Crim p tensile.

Vibration, sinusoidal.

Perform ance and Test Description

Product is designed to m eet electrical, m echanical and environm ental perform ance requirem ents

specified in Figure 1. Unless otherwise specified, all tests shall be perform ed at am bient environm ental

conditions per Test Specification 109-1.

Test Requirem ents and Procedures Sum m ary

Test Description

Meets requirem ents of product

drawing.

2.5 m illiohm s m axim um .

1000 m egohm s m inim um .

1500 vac at sea level.

30 C m axim um tem perature rise at

specified current of 31 am peres ac.

Solderable area shall have

m inim um of 95% solder coverage.

No discontinuities of 1

m icrosecond or longer duration.

See Note.

W ire Size

( AW G)

18

16

14

12

Figure 1 (continued)

MECHANICAL

ELECTRICAL

Requirem ent

(Lbs m axim um )

Crim p Tensile

20

30

50

50

TE 109-6-7.

TE Spec 109-28-4.

TE Spec 109-29-1.

Visual, dim ensional and functional

per applicable quality inspection

plan and Certificate of

Conform ance.

Subject m ated contacts assem bled

in housing to 50 m v m axim um open

circuit at 1 am pere m axim um .

See Figure 3.

Test between adjacent contacts of

m ated sam ples ganged together.

Test between adjacent contacts of

m ated sam ples ganged together

and a m etal plate.

See Figure 4.

TE Spec 109-45-1 and 109-151.

Measure tem perature rise vs

current.

See Figures 5 and 6.

TE Spec 109-11-2.

Subject contacts to solderability.

TE Spec 109-16.

Determ ine crim p tensile at

m axim um rate of 1 inch per m inute.

TE Spec 109-21-1.

Subject m ated sam ples to 10-55-10

Hz traversed in 1 m inute at .06 inch

total excursion. 1.3 hours in each of

3 m utually perpendicular planes.

See Figure 7.

Procedure

108-11026

2 of 9