HEN-1.5/25-D12M-C Murata Power Solutions Inc, HEN-1.5/25-D12M-C Datasheet - Page 9

HEN-1.5/25-D12M-C

Manufacturer Part Number

HEN-1.5/25-D12M-C

Description

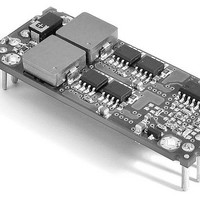

DC/DC Converters & Regulators 37.5W 12V-1.5V 25A Eighth-Brick

Manufacturer

Murata Power Solutions Inc

Series

HENr

Datasheet

1.HEN-1.525-D12M-C.pdf

(11 pages)

Specifications of HEN-1.5/25-D12M-C

Output Power

38 W

Input Voltage Range

10.2 V to 13.8 V

Number Of Outputs

1

Output Voltage (channel 1)

1.5 V

Output Current (channel 1)

25 A

Package / Case Size

Eighth Brick

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

HEN-1.5/25-D12M-C

Automated Assembly Production Notes

DATEL’s new high-efficiency DC/DC converters are designed for modern

surface-mount technology (SMT) automated assembly using screened

solder paste, "pick and place" component positioning and forced hot air

reflow oven soldering. If you are new to SMT techniques and have a volume

application, these features save time, cost and improve manufacturing

efficiency. DATEL’s DC/DC assembly operations themselves make extensive

use of such techniques.

Even if you have previous SMT experience, you should read the sections

below on solder reflow profiles and heat shields. This information is not

intended to replace the documentation for your SMT system. We assume

that you are already experienced with all the components of your SMT

system.

This section will discuss several SMT issues, including:

Mechanical Configuration of Input/Output Connections

These new converters are supplied either using traditional through-hole

pins or SMT leads. (Note that some models are offered only with lead

mounting). The pin options insert into plated-through holes in the host pcb.

Be aware that some heat dissipation is carried off by either the pins or

leads. The Derating Curves assume that some additional pad area is avail-

able on your host pcb to absorb the heat.

The lead option uses either short tabs in "gullwing" style or standoff leads

under the converter. The gullwing leads typically are copper alloy with 150

microinches of tin plating. Solder paste (typically 0.008" to 0.009" thick) is

applied to the host pcb using a solder mask pressure screening technique

and the board is heated and cooled long enough for the solder to reflow

and adhere to both the host pads and the converter’s mounting leads.

After such mounting, the entire mechanical mounting load is carried by the

solder. Obviously the converters must be accurately positioned all during

the solder reflow period. Where solder surface tension is sufficient to force

tiny components into position, these larger converters may not move and

must be accurately positioned by your SMT system.

Part Handling and Supply

SMT eighth- and quarter-brick DC/DC converters (plus installed heat

shields if used) are supplied in JEDEC-standard 5.35" by 12.4" waffle trays

which are compatible with the feeders on industry-standard pick-and-place

machines.

Since the converters are larger and heavier than many other components,

make sure your system can reliably remove the units from their trays, move

I/O Mechanical Configuration

Part Handling and Supply

Printed Circuit Board (pcb) Mounting

Soldering using Reflow Technology

Temperature Profiling

Heat Shields and Removal

www.murata-ps.com

them to the host pcb and accurately position them. The plastic heat shield

(see below) doubles as a vacuum pickup area.

Heatsinks

If you are using the preinstalled heatsink from DATEL, proceed normally

with surface mounting per the information in this section (the heat shield

fits completely over the heatsink). However, if you wish to add the heatsink

after receiving the converters and heatsink separately, you must install the

heatsink before solder reflow. Essentially, install the heatsink then place

the assembled converters back in the tray for surface mount positioning.

Please observe the torquing and assembly procedure discussed earlier for

the heatsink.

Pick and Place pcb Mounting

The main issues here are pad area, orientation, positioning accuracy,

vacuum pickup and coplanarity. DATEL recommends that pcb pads to

interface with the DC/DC converter should be sized as shown in the dia-

gram below. The pads footprint accommodates the positioning accuracy of

your SMT equipment and manufactured tolerances of the DC/DC mounting

leads.

Orientation: When loaded into JEDEC trays, these converters are all

oriented in the same direction. See the diagram below. For the LEN and

HEN series, a notch is placed on the top of the case (on the removal tabs) to

indicate the pin 1 position. You should visually inspect the tray to be sure of

this orientation.

On the bottom of the converter, the LEN and HEN series include optical

fiducial marks viewable by your SMT imaging system. See the attached

diagram. Observing from the bottom, your SMT imaging camera should find

these marks to identify the converter and verify pin 1. On most pick-and-

place systems, during head transit, the imaging system will automatically

fine tune the end mounting position of the converter using image compari-

sons from these fiducials or other reference marks you have chosen.

The fiducial marks are placed fairly close together because most imaging

systems have a one inch or less observing area since most SMT parts are

considerably smaller than these converters. You may prefer to train your

imaging system to use a corner of the converter or an I/O lead.

Single Output, Non Isolated, 12VIN, 0.8-5VOUT

Figure 6. Recommended SMT Mounting Pad Dimensions

Technical enquiries email: sales@murata-ps.com, tel:

25 Amp, High di/dt DC/DC Converters

HEN D12 Models

MDC_HEN-D12.B01 Page 9 of 11

+1 508 339 3000