HEN-1.5/25-D12M-C Murata Power Solutions Inc, HEN-1.5/25-D12M-C Datasheet - Page 10

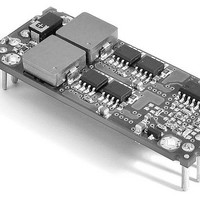

HEN-1.5/25-D12M-C

Manufacturer Part Number

HEN-1.5/25-D12M-C

Description

DC/DC Converters & Regulators 37.5W 12V-1.5V 25A Eighth-Brick

Manufacturer

Murata Power Solutions Inc

Series

HENr

Datasheet

1.HEN-1.525-D12M-C.pdf

(11 pages)

Specifications of HEN-1.5/25-D12M-C

Output Power

38 W

Input Voltage Range

10.2 V to 13.8 V

Number Of Outputs

1

Output Voltage (channel 1)

1.5 V

Output Current (channel 1)

25 A

Package / Case Size

Eighth Brick

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

HEN-1.5/25-D12M-C

In the drawing below, these dimensions are intended for initial search for

these marks by your camera. There will be tiny variations in absolute posi-

tion from unit to unit.

If you use a camera above the pcb after placement on the solder paste, do

not rely on the inkjet marking on the heat shield to verify proper orientation.

Use the pin 1 notch instead.

Coplanarity: DATEL manufactures these converters with very flat mounting

leads (see coplanarity specs) however your host pcb must also be flat for a

successful mounting. Be aware of possible warping of the pcb under heat

gradients and/or humidity conditions. The solder paste will tolerate a small

amount of mismatch and will tend to “wet” the entire pad area by capillary

action if the temperatures are correct.

Vacuum Pickup: Select the vacuum collet on your SMT placement system

for the weight and size of the DC/DC converter. Note that units with

heatsinks are slightly heavier. Tests at DATEL have shown that excellent

acceleration and transit head speed are available for these converters if

the collet size is proper and the vacuum is sufficient. When positioning the

vacuum collet, use the geometric center of the heat shield as the pickup

area since the center of gravity is very close.

Soldering

Reflow technology works well for small parts. However, larger components

such as these DC/DC’s with higher thermal mass may require additional

Figure 7. Fiducial Mark Location

www.murata-ps.com

reflow time (but not enough to disturb smaller parts also being reflowed

concurrently with the DC/DC). When this is combined with higher tem-

perature lead-free solders (or solders with reduced heavy metals), there is

increased risk of reheating components inside the DC/DC enough so that

they either change positions (and possibly stop functioning) or the compo-

nents are damaged by the heat.

For these reasons, DATEL developed disposable heat shields using high

temperature plastic. The DC/DC is installed and reflowed with the shield in

place. After successful reflow and cooling, and before washing, the heat

shield should be removed.

Temperature Profiling

We wish to ramp the temperature up and down to successfully reflow the

solder without heat damage. Each reflow oven, humidity conditions, solder

paste type, oven feed rate, and the number of heat zones all require a dif-

ferent profile. Therefore you may have to experiment.

Since these converters are constructed using high temperature solders,

there will be no heat problems on your host pcb using traditional solder

with 63% lead and 37% tin with a melting point of +183°C. Device lead

temperature must remain below 230°C for less than 75 seconds, assuming

that the heat shield is in place. DATEL uses a 216°C melt lead-free tin/

silver/copper alloy to assemble these converters.

There are several lead-free solders suitable for your host pcb depending

on your SMT system and whatever local certification and environmental

regulations you must observe. Contact DATEL if you need specific advice.

Heat Shield

Careful thermocouple testing has shown that the interior of the DC/DC

under the heat shield is tens of degrees cooler than the outside ambient

temperature for typical reflow profiles. This protects internal components

and limits the amount of reflow where it is not desired. The heat shield also

includes marking for product identification and a date/lot code.

On LEN and HEN models, the heat shield is attached to the converter using

molded plastic pins on the heat shield interior which insert into recessed

dimples in the pinframe. An extra molded pin on the heat shield at the pin

1 location (and corresponding notch on the pcb) can only be installed one

way properly on the pinframe. If the shield accidentally comes loose, it may

be reinstalled by aligning the pins and dimples.

To remove the shield from the converter, after successful mounting and

cooling, squeeze the heat shield ears inward toward the converter body and

pull the shield upwards. Discard or recycle the shield. If you are using a flux

wash cycle, remove the heat shield before washing to avoid coming loose

inside the washer.

Single Output, Non Isolated, 12VIN, 0.8-5VOUT

Technical enquiries email: sales@murata-ps.com, tel:

25 Amp, High di/dt DC/DC Converters

HEN D12 Models

MDC_HEN-D12.B01 Page 10 of 11

+1 508 339 3000