STBVP6 BANNER ENGINEERING, STBVP6 Datasheet - Page 5

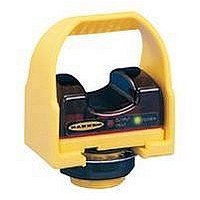

STBVP6

Manufacturer Part Number

STBVP6

Description

Photoelectric Touch Buttons

Manufacturer

BANNER ENGINEERING

Specifications of STBVP6

Output Current

150mA

Supply Voltage Range Dc

10V To 30V

Function

Proximity

Primary Type

Photoelectric

Technology

Photoelectric

Accessories Available

Cordsets, Field Covers and Brackets

Lead Free Status / Rohs Status

RoHS Exempt Product

The following example illustrates the

use of the formula to calculate

separation distance for a part-

revolution clutch machine. This

example uses 0.50 seconds as a typical

value for T s and 0.025 seconds for T r

and T h :

In this example, both hand controls

must be located no closer than 35"

from the nearest hazard point.

Hand controls must be mounted a safe

distance from moving machine parts, as

determined by OSHA Regulation CFR

1910.217 (c) (3) (vii) and (viii). It must not

be possible for the operator or other non-

qualified persons to relocate them. Failure

to establish and maintain the required

safety distance could result in serious

injury or death.

Example Separation Distance (D s )

K = 63" per second,

T s = 0.50 seconds

T r = 0.025 seconds

T h = 0.025 seconds

D s = K x (T s + T r + T h )

!

= 63" (0.50 + 0.025 + 0.025)

= 35"

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

stop-time measuring device)

Calculation

WARNING ...

Location of Touch

Button Controls

(measured by a

•

Minneapolis, U.S.A.

STB Series Self-Checking Optical Touch Buttons

Separation Distance

Both hand controls must be located far enough away from the nearest hazard point that

the operator cannot reach the hazard with a hand or other body part before the hazardous

motion ceases (ANSI B11.19, 4.2.4.3.2). This is the “separation distance,” and may be

calculated as follows [see OSHA CFR 1910.217 (c) (3) (vii) & (viii)].

For Part-Revolution Clutch Machinery

Where the machine and its controls allow the machine to stop motion during the

hazardous portion of the machine cycle, use the following formula:

For Full-Revolution Clutch Machinery

Where the machine and its controls are designed to complete a full machine cycle,

once activated, use the following formula:

For both formulas:

NOTES:

1)

2)

3)

D s = the separation distance in inches,

K

T s = the stop time (in seconds) of the machine, measured from the application

T r = the response time of the Two-Hand-Control safety module as measured

T h = the response time of the slowest hand control (from the time when a hand

T m = the maximum time (in seconds) the machine takes to cease all motion after

The OSHA-recommended hand speed constant K has been determined by various studies, and although

these studies indicate speeds of 63"/sec to over 100"/sec, they are not conclusive determinations. The

employer should consider all factors, including the physical ability of the operator, when determining

the value of K to be used.

T s is usually measured by a stop-time measuring device. If the specified machine stop time is used,

add at least 20% as a safety factor to account for brake system deterioration. If the stop-time of the two

redundant machine control elements is unequal, the slower of the two times must be used for

calculating the separation distance.

T h is usually insignificant for purely mechanical switches. However, T h should be considered for

separation distance calculation when using electronic or electromechanical (i.e. powered) hand controls.

= 63" per second (the hand speed constant currently accepted by OSHA; see

NOTE 1, below),

of the “stop” signal to the final ceasing of all motion, including stop times

of all relevant control elements, and measured at maximum machine

velocity (see NOTE 2, below),

from the time either hand disengages a hand control

disengages that control until the switch opens; see NOTE 3, below)

it has been tripped. For full-revolution clutch presses with only one

engaging point, T m is equal to the time necessary for one and one-half

revolutions of the crankshaft. For full-revolution clutch presses with more

than one engaging point, T m is calculated as follows:

T m = (

N = number of clutch engaging points per revolution

T cy = time (in seconds) necessary to complete one revolution of the crankshaft

1

where:

/

2

+

1

/

N

) x T cy

D s = K x (T s + T r + T h )

D s = K x (T m + T r + T h )

page

5