GW5BWF15L00 Sharp Microelectronics, GW5BWF15L00 Datasheet - Page 13

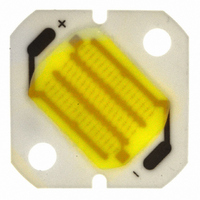

GW5BWF15L00

Manufacturer Part Number

GW5BWF15L00

Description

LED MOD 7WATT ZENIGATA 5000K

Manufacturer

Sharp Microelectronics

Type

Without Connectorr

Datasheet

1.GW5BWF15L00.pdf

(13 pages)

Specifications of GW5BWF15L00

Color

White

Luminous Flux @ Current - Test

540 lm

Current - Test

640mA

Current - Max

640mA

Driver Circuitry

No

Voltage

10.2V

Wavelength

5000K

Configuration

Single

With Connector

No

Voltage - Input

10.2V

Power - Input

7W

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Interface

-

Other names

425-2738

GW5BWF15L02

GW5BWF15L02

⑤ Module surface strength

⑥ Connecting method

⑦ Static electricity

⑧ Drive method

⑨ Cleaning

⑩ Color-tone variation

⑪ Safety

※ This specification is reference.

Module surface is subject to mechanical stress. Applying stress to surface of modules results in damage on resin,

and inside-failure.

Put the board on materials whose conductivity is poor enough not to radiate heat of soldering.

Avoid touching yellow phosphor with soldering iron.

This product is not designed for reflow and flow soldering.

This product is subject to static electricity, so take measures to cope with it.

Install circuit protection device to drive circuit, if necessary.

Module is composed of LEDs connected in both series and parallel. Constant voltage power supply

runs off more than specified current amount due to lowered VF caused by temperature rise.

Constant current power supply is recommended to drive.

Any reverse voltage cannot be applied to LEDs when they are in operation or not.

Design a circuit so that any flow of reverse or forward voltage can not be applied to LEDs when they are

out of operation.

Avoid cleaning, since silicone resin is eroded by it.

Chromaticity of this product is monitored by integrating sphere right after the operation.

Chromaticity varies depending on measuring method, light spread condition, or ambient temperature.

Please verify your actual conditions before use.

Looking directly at LEDs for a long time may result in hurt your eyes.

In case that excess current(over ratings) are supplied to the device, hazardous phenomena including abnormal

heat generation, emitting smoke, or catching fire can be caused.

Take appropriate measures to excess current and voltage.

In case of solder connecting method, apply solder to the leads

by soldering iron with thermo controller (tip temperature 380℃), within 10seconds per one place.

In case of solder connecting method, there is a possibility of fatigue failure by heat.

Please fix the leads in such case to protect from short circuit or leakage of electricity caused by contact.

Please confirm the safety standards or regulations of application devices.

MODEL No.

GW5BWF15L00

DG-087005

Page

12/12