GW5BWF15L00 Sharp Microelectronics, GW5BWF15L00 Datasheet - Page 12

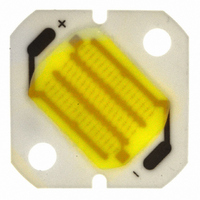

GW5BWF15L00

Manufacturer Part Number

GW5BWF15L00

Description

LED MOD 7WATT ZENIGATA 5000K

Manufacturer

Sharp Microelectronics

Type

Without Connectorr

Datasheet

1.GW5BWF15L00.pdf

(13 pages)

Specifications of GW5BWF15L00

Color

White

Luminous Flux @ Current - Test

540 lm

Current - Test

640mA

Current - Max

640mA

Driver Circuitry

No

Voltage

10.2V

Wavelength

5000K

Configuration

Single

With Connector

No

Voltage - Input

10.2V

Power - Input

7W

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Interface

-

Other names

425-2738

GW5BWF15L02

GW5BWF15L02

7. Precautions

① Storage conditions

② Usage conditions

③ Heat radiation

④ Installation

Please follow the conditions below.

・Before opened: Temperature 5~30℃, humidity less than 60%RH

・After opened: Temperature 5~30℃, humidity less than 60%RH (Please apply soldering within 1 week.)

・Avoid exposing to air with corrosive gas.

The products are not designed for the use under any of the following conditions.

Please confirm their performance and reliability well enough if you use under any of the following conditions;

・ In a place with a lot of moisture, dew condensation, briny air, and corrosive gas

・Under the direct sunlight, outdoor exposure, and in a dusty place.

・In water, oil, medical fluid, and organic solvent.

If the forward current(IF) is applied to single-state module at 360mA, there is a risk of damaging module

or emitting smoke.

Equip with specified heat radiator, and avoid heat stuffed inside the module.

Applying thermal conductive sheet or grease between module and heat radiator enables heat to radiate effectively.

Material of board is alumina ceramic. If installed inappropriately, trouble of no radiation may occur due to

board crack. Please take particular notice of install method.

Further information on installation, refer to the following cautions.

・ Apply ether screws or adhesives, or both of them when installed to heat radiator.

・ Refer to recommended dimensions when installing with screws.

・ Screw torque: Within 0.2Nm

・ It is recommended to apply screws which use low corrosive materials such as Stainless steel.

・ Avoid convexly uneven boards.

・ It is recommended to apply thermal conductive sheet or grease with adhesiveness and heat radiating-

If exposed, electrode surface would be damaged, which may affect soldering.

(Cl, H

In case of applying adhesive only, check the effectiveness before fixing.

In case of screw, apply thread locker in order to prevent loosening.

If LED comes off from the heat radiator, unusual temperature rise entails hazardous phenomena including

device deterioration, coming off of solder at leads, and emitting smoke.

If it is inefficient to tighten screws, apply locker to prevent loosening.

Avoid applying flat-head screws, which cause board crack due to applying stress to screw holes.

Those convex boards are subject to crack when tightening screws.

adhesives, because of thermal and mechanical combination between module and heat radiator.

However, depending on their thickness, board crack may be entailed by warped board, which is

caused when tightening screws. So please check your actual conditions carefully as for the screw torque.

※ This specification is reference.

2

S, NH

3

, SO

2

, NO

X

, etc.).

MODEL No.

GW5BWF15L00

DG-087005

Page

11/12