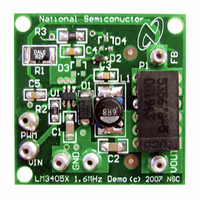

LM3405XEVAL National Semiconductor, LM3405XEVAL Datasheet - Page 12

LM3405XEVAL

Manufacturer Part Number

LM3405XEVAL

Description

BOARD EVALUATION LM3405X

Manufacturer

National Semiconductor

Series

PowerWise®r

Specifications of LM3405XEVAL

Current - Output / Channel

1A

Outputs And Type

1, Non-Isolated

Voltage - Output

0.2 ~ 13.5 V

Features

Dimmable

Voltage - Input

3 ~ 15V

Utilized Ic / Part

LM3405

Kit Contents

Board, Datasheet

Svhc

No SVHC (15-Dec-2010)

Kit Features

Cycle-by-Cycle Current Limit,

Rohs Compliant

No

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

www.national.com

BOOST CAPACITOR (C3)

A 0.01µF ceramic capacitor with a voltage rating of at least

6.3V is sufficient. The X7R and X5R MLCCs provide the best

performance.

POWER LOSS ESTIMATION

The main power loss in LM3405 includes three basic types of

loss in the internal power switch: conduction loss, switching

loss, and gate charge loss. In addition, there is loss associ-

ated with the power required for the internal circuitry of IC.

The conduction loss is calculated as:

If the inductor ripple current is fairly small (for example, less

than 40%) , the conduction loss can be simplified to:

The switching loss occurs during the switch on and off tran-

sition periods, where voltage and current overlap resulting in

power loss. The simplest means to determine this loss is to

empirically measure the rise and fall times (10% to 90%) of

the voltage at the switch pin.

Switching power loss is calculated as follows:

The gate charge loss is associated with the gate charge Q

required to drive the switch:

The power loss required for operation of the internal circuitry:

I

1.8mA for the LM3405.

The total power loss in the IC is:

An example of power losses for a typical application is shown

in Table 2:

Q

D is calculated to be 0.37

is the quiescent operating current, and is typically around

R

T

T

V

DS(ON)

I

V

f

V

Q

OUT

RISE

FALL

OUT

SW

I

D1

Q

IN

G

P

Σ ( P

SW

Conditions

P

TABLE 2. Power Loss Tabulation

= 0.5 x V

INTERNAL

COND

P

COND

1.6MHz

300mΩ

1.8mA

0.45V

1.4nC

+ P

P

P

4.1V

1.0A

18ns

12ns

12V

INTERNAL

G

= P

IN

SW

= f

P

= I

x I

Q

COND

SW

F

+ P

F

= I

2

x f

x R

x V

Q

Q

= 448mW

SW

+ P

x V

+ P

IN

DS(ON)

x ( T

SW

P

IN

x Q

G

P

COND

P

P

SW

) = P

+ P

Q

G

G

RISE

x D

Power loss

G

INTERNAL

+ T

+ P

FALL

Q

111mW

288mW

22mW

27mW

)

G

12

PCB Layout Considerations

When planning layout there are a few things to consider when

trying to achieve a clean, regulated output. The most impor-

tant consideration when completing the layout is the close

coupling of the GND connections of the input capacitor C1

and the catch diode D1. These ground ends should be close

to one another and be connected to the GND plane with at

least two through-holes. Place these components as close to

the IC as possible. The next consideration is the location of

the GND connection of the output capacitor C2, which should

be near the GND connections of C1 and D1.

There should be a continuous ground plane on the bottom

layer of a two-layer board except under the switching node

island.

The FB pin is a high impedance node and care should be

taken to make the FB trace short to avoid noise pickup that

causes inaccurate regulation. The LED current setting resis-

tor R1 should be placed as close as possible to the IC, with

the GND of R1 placed as close as possible to the GND of the

IC. The V

the inductor and any other traces that are switching.

High AC currents flow through the V

so they should be as short and wide as possible. Radiated

noise can be decreased by choosing a shielded inductor.

The remaining components should also be placed as close

as possible to the IC. Please see Application Note AN-1229

for further considerations and the LM3405 demo board as an

example of a four-layer layout.

OUT

trace to LED anode should be routed away from

IN

, SW and V

OUT

traces,