YNV12T10-0G POWER ONE, YNV12T10-0G Datasheet - Page 7

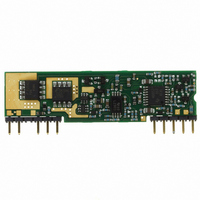

YNV12T10-0G

Manufacturer Part Number

YNV12T10-0G

Description

CONVERTER DC-DC 12V 10A SIP

Manufacturer

POWER ONE

Series

Yr

Type

Point of Load (POL) Non-Isolatedr

Datasheet

1.YNV12T10-0G.pdf

(25 pages)

Specifications of YNV12T10-0G

Output

0.75 ~ 5.5V

Number Of Outputs

1

Power (watts)

55W

Mounting Type

Through Hole

Voltage - Input

9.6 ~ 14V

Package / Case

10-SIP Module

1st Output

0.75 ~ 5.5 VDC @ 10A

Size / Dimension

2.00" L x 0.28" W x 0.54" H (50.8mm x 7.1mm x 13.7mm)

Power (watts) - Rated

55W

Operating Temperature

-40°C ~ 85°C

Efficiency

94%

Approvals

cUL, EN, UL

Package

10SIP

Output Current

10 A

Output Voltage

0.7525 to 5.5 V

Input Voltage

12 V

Output Power

50 W

Switching Regulator

Yes

Input Voltage Range

9.6 V to 14 V

Input Voltage (nominal)

12 V

Output Voltage (channel 1)

0.7525 V to 5.5 V

Output Current (channel 1)

10 A

Package / Case Size

SIP

Output Type

Regulated

Product

Non-Isolated / POL

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3rd Output

-

2nd Output

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

179-2377

depending on the required output voltage range

[k]

Control voltages with

shown in Table 2.

Protection Features

Input Undervoltage Lockout

Input undervoltage lockout is standard with this

converter. The converter will shut down when the

input voltage drops below a pre-determined

voltage; it will start automatically when Vin returns

to a specified range.

The input voltage must be at least 9.6V (typically

9V) for the converter to turn on. Once the

converter has been turned on, it will shut off when

the input voltage drops below typically 8.5V.

Output Overcurrent Protection (OCP)

The converter is protected against over-current

and short circuit conditions. Upon sensing an

overcurrent condition, the converter will enter

hiccup mode. Once over-load or short circuit

condition is removed, Vout will return to nominal

value.

Overtemperature Protection (OTP)

The converter will shut down under an over-

temperature condition to protect itself from

overheating caused by operation outside the

thermal derating curves, or operation in abnormal

conditions such as system fan failure. After the

converter

temperature, it will automatically restart.

MCD10202 Rev. 1.0, 24-Jun-10

V

0-REG

0.7525

1.0

1.2

1.5

1.8

2.0

2.5

3.3

5.0

5.5

[V]

Table 2: Control Voltage [VDC]

has cooled to

V

CTRL

0.700

0.684

0.670

0.650

0.630

0.617

0.584

0.530

0.417

0.384

(R

EXT

R

= 0)

EXT

9.6-14 VDC Input; 0.7525-5.5 VDC Programmable @ 10A

0 and

V

a safe operating

CTRL

(R

R

-0.097

-0.417

-0.631

-1.164

-2.017

-3.831

-4.364

0.700

0.436

0.223

EXT

EXT

= 15K)

15K are

YNV12T10 DC-DC Converter Data Sheet

Page 7 of 25

Safety Requirements

The

International safety regulatory requirements per

UL60950 and EN60950. The maximum DC

voltage between any two pins is Vin under all

operating conditions. Therefore, the unit has ELV

(extra low voltage) output; it meets SELV

requirements under the condition that all input

voltages are ELV.

The converter is not internally fused. To comply

with safety agencies requirements, a recognized

fuse with a maximum rating of 15 Amps must be

used in series with the input line.

Characterization

General Information

The converter has been characterized for many

operational aspects, to include thermal derating

(maximum load current as a function of ambient

temperature and airflow) for vertical and horizontal

mounting,

parameters, output ripple and noise, transient

response to load step-change, overload and short

circuit.

The figures are numbered as Fig. x.y, where x

indicates the different output voltages, and y

associates with specific plots (y = 1 for the vertical

thermal derating, …). For example, Fig. x.1 will

refer to the vertical thermal derating for all the

output voltages in general.

The following pages contain specific plots or

waveforms

Additional comments for specific data are provided

below.

Test Conditions

All thermal and efficiency data presented were

taken with the converter soldered to a test board,

specifically a 0.060” thick printed wiring board

(PWB) with four layers. The top and bottom layers

were not metalized. The two inner layers,

comprising two-ounce copper, were used to

provide traces for connectivity to the converter.

The lack of metalization on the outer layers as well

as the limited thermal connection ensured that

heat transfer from the converter to the PWB was

converter

www.power-one.com

efficiency,

associated

meets

start-up

North

with

the

and

American

converter.

shutdown

and