SQ48T10050-NBB0 POWER ONE, SQ48T10050-NBB0 Datasheet - Page 6

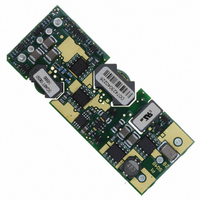

SQ48T10050-NBB0

Manufacturer Part Number

SQ48T10050-NBB0

Description

CONV DC-DC 48V IN 5V OUT 50W

Manufacturer

POWER ONE

Series

SQ48r

Type

Isolatedr

Datasheet

1.SQ48T15018-NBB0.pdf

(64 pages)

Specifications of SQ48T10050-NBB0

Output

5V

Number Of Outputs

1

Power (watts)

50W

Mounting Type

Through Hole

Voltage - Input

36 ~ 75V

Package / Case

8-DIP Module, 1/4 Brick

1st Output

5 VDC @ 10A

Size / Dimension

2.30" L x 0.90" W x 0.34" H (58.4mm x 22.9mm x 8.6mm)

Power (watts) - Rated

50W

Operating Temperature

-40°C ~ 85°C

Approvals

cUL, EN, UL

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

3rd Output

-

2nd Output

-

4th Output

-

Other names

179-2212

SQ48T10050-NAA0

SQ48T10050-NBBO

SQ48T10050-NAA0

SQ48T10050-NBBO

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

SQ48T10050-NBB0G

Manufacturer:

POWER-ONE

Quantity:

20 000

Test Conditions

All data presented were taken with the converter

soldered to a test board, specifically a 0.060” thick

printed wiring board (PWB) with four layers. The top

and bottom layers were not metalized. The two inner

layers, comprised of two-ounce copper, were used to

provide traces for connectivity to the converter.

The lack of metalization on the outer layers as well

as the limited thermal connection ensured that heat

transfer from the converter to the PWB was

minimized. This provides a worst-case but consistent

scenario for thermal derating purposes.

All measurements requiring airflow were made in the

vertical and horizontal wind tunnel using Infrared (IR)

thermography and thermocouples for thermometry.

Ensuring components on the converter do not

exceed their ratings is important to maintaining high

reliability. If one anticipates operating the converter

at or close to the maximum loads specified in the

derating curves, it is prudent to check actual

operating

Thermographic imaging is preferable; if this capability

is not available, then thermocouples may be used.

The use of AWG #40 gauge thermocouples is

recommended to ensure measurement accuracy.

Careful routing of the thermocouple leads will further

minimize measurement error. Refer to Fig. E for the

optimum measuring thermocouple location.

Thermal Derating

Load current vs. ambient temperature and airflow

rates are given in Fig. x.1 to Fig. x.4 for through-hole

and surface-mount versions. Ambient temperature

was varied between 25 °C and 85 °C, with airflow

rates from 30 to 500 LFM (0.15 to 2.5 m/s), and

vertical and horizontal converter mounting.

For each set of conditions, the maximum load current

was defined as the lowest of:

(i) The output current at which any FET junction

temperature does not exceed a maximum specified

temperature

thermographic image, or

SEP 14, 2005 revised to NOV 06, 2006

Fig. E: Location of the thermocouple for thermal testing.

temperatures

(120°C)

as

in

indicated

the

application.

by

the

Page 6 of 64

36-75 VDC Input; 1.0-12 VDC Output

(ii) The nominal rating of the converter (4 A on 12 V,

5.3 A on 8.0 V, 8 A on 6.0 V, 10 A on 5.0 V, and 15 A

on 3.3 – 1.0 V)).

During normal operation, derating curves

maximum FET temperature less or equal to 120 °C

should not be exceeded. Temperature on the PCB at

thermocouple location shown in Fig. E should not

exceed 118 °C in order to operate inside the derating

curves.

Efficiency

Fig. x.5 shows the efficiency vs. load current plot for

ambient temperature of 25 ºC, airflow rate of 300 LFM

(1.5 m/s) with vertical mounting and input voltages of

36 V, 48 V and 72 V. Also, a plot of efficiency vs. load

current, as a function of ambient temperature with

Vin = 48 V, airflow rate of 200 LFM (1 m/s) with

vertical mounting is shown in Fig. x.6.

Power Dissipation

Fig. x.7 shows the power dissipation vs. load current

plot for Ta = 25 ºC, airflow rate of 300 LFM (1.5 m/s)

with vertical mounting and input voltages of 36 V, 48

V and 72 V. Also, a plot of power dissipation vs. load

current, as a function of ambient temperature with

Vin = 48 V, airflow rate of 200 LFM (1 m/s) with

vertical mounting is shown in Fig. x.8.

Startup

Output

transient using the ON/OFF pin for full rated load

currents (resistive load) are shown without and with

external load capacitance in Fig. x.9 and Fig. x.10,

respectively.

Ripple and Noise

Fig. x.13 shows the output voltage ripple waveform,

measured at full rated load current with a 10 µF

tantalum and 1 µF ceramic capacitor across the

output. Note that all output voltage waveforms are

measured across a 1 µF ceramic capacitor.

The input reflected ripple current waveforms are

obtained using the test setup shown in Fig x.14. The

corresponding waveforms are shown in Fig. x.15 and

Fig. x.16.

SQ48 DC-DC Series Data Sheet

voltage

waveforms,

during

www.power-one.com

the

turn-on

with