LTW-C192TL2 Lite-On Electronics, LTW-C192TL2 Datasheet - Page 10

LTW-C192TL2

Manufacturer Part Number

LTW-C192TL2

Description

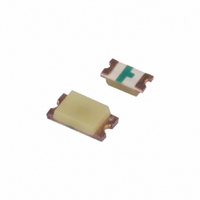

LED WHITE YELLOW 38MCD SMD 0603

Manufacturer

Lite-On Electronics

Datasheet

1.LTW-C192TL2.pdf

(11 pages)

Specifications of LTW-C192TL2

Package / Case

0603 (1608 Metric)

Viewing Angle

130°

Color

White

Millicandela Rating

38mcd

Current - Test

2mA

Wavelength - Dominant

6700K

Voltage - Forward (vf) Typ

2.7V

Lens Type

Diffused, Yellow Tinted

Lens Style/size

Rectangle, 1.15mm x 0.8mm

Size / Dimension

1.60mm L x 0.80mm W

Height

0.40mm

Mounting Type

Surface Mount

Resistance Tolerance

6700K

Led Size

0603

Illumination Color

White

Lens Color/style

Yellow

Operating Voltage

2.45 V to 2.95 V

Luminous Intensity

21 mcd to 55 mcd

Mounting Style

SMD/SMT

Operating Current

2 mA

Maximum Operating Temperature

+ 80 C

Minimum Operating Temperature

- 20 C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Luminous Flux @ Current - Test

-

Wavelength - Peak

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

160-1741-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LTW-C192TL2

Manufacturer:

LITEON

Quantity:

40 000

BNS-OD-C131/A4

Part No. : LTW-C192TL2

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current, low forward

voltage, or “ no lightup ” at low currents.

To verify for ESD damage, check for “ lightup ” and Vf of the suspect LEDs at low currents.

The Vf of “ good ” LEDs should be >2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP product.

7. Reliability Test

8. Others

Environmental

Classification

Endurance

The appearance and specifications of the product may be modified for improvement without prior notice.

Test

Test

High Temperature

High Temperature

Low Temperature

High Humidity

Operation Life

Temperature

Solderability

Resistance

IR-Reflow

Test Item

Thermal

Cycling

Storage

Storage

Storage

Solder

Shock

LITE-ON TECHNOLOGY CORPORATION

Ta= Under Room Temperature As Per Data Sheet

Maximum Rating

*Test Time= 1000HRS (-24HRS,+72HRS)*@20mA.

IR-Reflow In-Board, 2 Times

Ta= 65±5℃,RH= 90~95%

*Test Time= 240HRS±2HRS

Ta= 105±5℃

*Test Time= 1000HRS (-24HRS,+72HRS)

Ta= -55±5℃

*Test Time=1000HRS (-24HRS,+72H RS)

105℃ ~ 25℃ ~ -55℃ ~ 25℃

30mins 5mins

10 Cycles

IR-Reflow In-Board, 2 Times

85 ± 5℃ ~ -40℃ ± 5℃

10mins

T.sol= 260 ± 5℃

Dwell Time= 10 ± 1secs

Ramp-up rate(217℃ to Peak) +3℃/ second max

Temp. maintain at 175(±25)℃ 180 seconds max

Temp. maintain above 217℃ 60-150 seconds

Peak temperature range 260℃+0/-5℃

Time within 5°C of actual Peak Temperature (tp)

20-40 seconds

Ramp-down rate +6℃/second max

T.sol= 235 ± 5℃

Immersion time 2±0.5 sec

Immersion rate 25±2.5 mm/sec

Coverage ≧95% of the dipped surface

P r o p e r t y o f L i t e - O n O n l y

10mins 10 Cycles

Test Condition

30mins 5mins

Page :

MIL-STD-750D:1026 (1995)

MIL-STD-883D:1005 (1991)

JIS C 7021:B-1 (1982)

MIL-STD-202F:103B(1980)

JIS C 7021:B-11(1982)

MIL-STD-883D:1008 (1991)

JIS C 7021:B-10 (1982)

JIS C 7021:B-12 (1982)

MIL-STD-202F:107D (1980)

MIL-STD-750D:1051(1995)

MIL-STD-883D:1010 (1991)

JIS C 7021:A-4(1982)

MIL-STD-202F:107D(1980)

MIL-STD-750D:1051(1995)

MIL-STD-883D:1011 (1991)

MIL-STD-202F:210A(1980)

MIL-STD-750D:2031(1995)

JIS C 7021:A-1(1982)

MIL-STD-750D:2031.2(1995)

J-STD-020(1999)

MIL-STD-202F:208D(1980)

MIL-STD-750D:2026(1995)

MIL-STD-883D:2003(1991)

IEC 68 Part 2-20

JIS C 7021:A-2(1982)

Reference Standard

10

of

11