LTW-270TLA Lite-On Electronics, LTW-270TLA Datasheet - Page 9

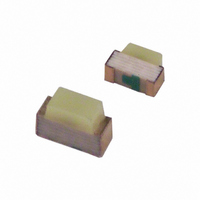

LTW-270TLA

Manufacturer Part Number

LTW-270TLA

Description

LED WHITE YELLOW SIDE VIEW 95MCD

Manufacturer

Lite-On Electronics

Datasheet

1.LTW-270TLA.pdf

(12 pages)

Specifications of LTW-270TLA

Led Size

1.6 mm x 0.6 mm

Illumination Color

White

Operating Voltage

3.4 V

Wavelength

468 nm

Mounting Style

SMD/SMT

Operating Current

20 mA

Lens Shape

Rectangular

Package / Case

0603 (1608 Metric)

Viewing Angle

130°

Color

White

Millicandela Rating

112.5mcd

Current - Test

10mA

Wavelength - Dominant

6700K

Voltage - Forward (vf) Typ

3.1V

Lens Type

Diffused, Yellow Tinted

Lens Style/size

Rectangle, 1.2mm x 0.6mm

Size / Dimension

1.60mm L x 1.15mm W

Height

0.60mm

Mounting Type

Surface Mount, Right Angle

Resistance Tolerance

6700K

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Luminous Flux @ Current - Test

-

Wavelength - Peak

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

160-1739-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LTW-270TLA

Manufacturer:

LITEON

Quantity:

40 000

Company:

Part Number:

LTW-270TLA

Manufacturer:

Lite-On Inc

Quantity:

25 463

BNS-OD-C131/A4

Part No. : LTW-270TLA

1. Application

2. Storage

3. Cleaning

4. Soldering

Soldering notes:

The package is sealed:

The LEDs should be stored at 30°C or less and 90%RH or less. And the LEDs are limited to use within

one year, while the LEDs is packed in moisture-proof package with the desiccants inside.

The package is opened:

The storage ambient for the LEDs should not exceed 30°C temperature or 60% relative humidity.

It is recommended that LEDs out of their original packaging are IR-reflowed within one week.

For extended storage out of their original packaging, it is recommended that the LEDs be stored in a sealed

container with appropriate desiccant, or in a desiccators with nitrogen ambient.

LEDs stored out of their original packaging for more than one week should be baked at about 60 deg C for at least

20 hours before solder assembly.

The LEDs described here are intended to be used for ordinary electronic equipment (such as office

equipment, communication equipment and household applications).Consult Liteon’s Sales in advance

for information on applications in which exceptional reliability is required, particularly when the failure

or malfunction of the LEDs may directly jeopardize life or health (such as in aviation, transportation,

traffic control equipment, medical and life support systems and safety devices).

Use alcohol-based cleaning solvents such as isopropyl alcohol to clean the LED if necessary.

Recommended soldering conditions:

Pre-heat

Pre-heat time

Peak temperature

Soldering time

Because different board designs use different number and types of devices, solder pastes, reflow ovens,

and circuit boards, no single temperature profile works for all possible combinations.

However, you can successfully mount your packages to the PCB by following the proper guidelines and

PCB-specific characterization.

LITE-ON Runs both component-level verification using in-house KYRAMX98 reflow chambers and

board-level assembly.

The results of this testing are verified through post-reflow reliability testing.

Profiles used at LITE-ON are based on JEDEC standards to ensure that all packages can be successfully

and reliably surface mounted.

Figure on page3 shows a sample temperature profile compliant to JEDEC standards.

You can use this example as a generic target to set up your reflow process.

You should adhere to the JEDEC profile limits as well as specifications and recommendations from the

solder paste manufacturer to avoid damaging the device and create a reliable solder joint.

Reflow soldering

LITE-ON TECHNOLOGY CORPORATION

150~200°C

120 sec. Max.

260°C Max.

10 sec. Max.(Max. two times)

P r o p e r t y o f L i t e - O n O n l y

CAUTIONS

Temperature

Soldering time

Soldering iron

Page :

300°C Max.

3 sec. Max.

(one time only)

9

of

12