LTW-150TK Lite-On Electronics, LTW-150TK Datasheet - Page 10

LTW-150TK

Manufacturer Part Number

LTW-150TK

Description

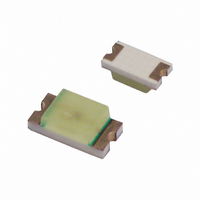

LED WHITE YELLOW 260MCD 1206

Manufacturer

Lite-On Electronics

Type

Uni-Colorr

Specifications of LTW-150TK

Led Size

3.2 mm x 1.6 mm

Illumination Color

White

Operating Voltage

3.2 V

Luminous Intensity

260 mcd

Mounting Style

SMD/SMT

Operating Current

20 mA

Lens Shape

Rectangular

Maximum Operating Temperature

+ 80 C

Minimum Operating Temperature

- 20 C

Package / Case

1206 (3216 Metric)

Viewing Angle

130°

Color

White

Millicandela Rating

260mcd

Current - Test

20mA

Wavelength - Dominant

15000K

Voltage - Forward (vf) Typ

3.2V

Lens Type

Diffused, Yellow Tinted

Lens Style/size

Rectangle, 2.06mm x 1.6mm

Size / Dimension

3.20mm L x 1.60mm W

Height

1.10mm

Mounting Type

Surface Mount

Resistance Tolerance

15000K

Package Type

SMD

Emitting Color

Yellow

Test Current (it)

20mA

Forward Current

20mA

Forward Voltage

3.8V

Product Length (mm)

3.2mm

Product Height (mm)

1.1mm

Product Depth (mm)

1.6mm

Mounting

Surface Mount

Shape Type

Rectangular

Chip Material

InGaN

Main Category

Chip LED

Number Of Elements

1

Pin Count

2

Operating Temperature Classification

Commercial

Operating Temp Range

-20C to 80C

Reverse Voltage

5V

Power Dissipation

70mW

Lens Dimensions

2.06X1.6X0.6mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Luminous Flux @ Current - Test

-

Wavelength - Peak

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

160-1737-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LTW-150TK

Manufacturer:

LITEON

Quantity:

40 000

Company:

Part Number:

LTW-150TK

Manufacturer:

Lite-On Inc

Quantity:

81 136

BNS-OD-C131/A4

or “ no lightup ” at low currents.

5. Drive Method

Part No. : LTW-150TK

6. ESD (Electrostatic Discharge)

Static Electricity or power surge will damage the LED.

Suggestions to prevent ESD damage:

An LED is a current-operated device. In order to ensure intensity uniformity on multiple LEDs connected in

parallel in an application, it is recommended that a current limiting resistor be incorporated in the drive circuit,

in series with each LED as shown in Circuit A below.

(A) Recommended circuit.

(B) The brightness of each LED might appear different due to the differences in the I-V characteristics

Use of a conductive wrist band or anti-electrostatic glove when handling these LEDs.

All devices, equipment, and machinery must be properly grounded.

Work tables, storage racks, etc. should be properly grounded.

Use ion blower to neutralize the static charge which might have built up on surface of the LED’s plastic

lens as a result of friction between LEDs during storage and handling.

ESD-damaged LEDs will exhibit abnormal characteristics such as high reverse leakage current, low forward voltage,

To verify for ESD damage, check for “ lightup ” and Vf of the suspect LEDs at low currents.

The Vf of “ good ” LEDs should be >2.0V@0.1mA for InGaN product and >1.4V@0.1mA for AlInGaP product.

of those LEDs.

Circuit model A

LITE-ON TECHNOLOGY CORPORATION

LED

P r o p e r t y o f L i t e - O n O n l y

Circuit model B

LED

Page :

10

of

12