HFBR-2521Z Avago Technologies US Inc., HFBR-2521Z Datasheet - Page 3

HFBR-2521Z

Manufacturer Part Number

HFBR-2521Z

Description

RECEIVER FIBER OPTIC 600NM 5MBD

Manufacturer

Avago Technologies US Inc.

Specifications of HFBR-2521Z

Data Rate

5MBd

Voltage - Supply

4.75 V ~ 5.25 V

Power - Minimum Receivable

-43dBm

Current - Supply

10mA

Function

Designed for use in high and low volume cost assembly processes such as auto insertion and wave soldering.

Product

Receiver

Wavelength

600 nm

Diode Capacitance

86 pF

Pulse Width Distortion

7 us

Maximum Output Current

25 mA

Operating Supply Voltage

- 0.5 V to 7 V

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 40 C

Data Rate Max

115Kbps

Forward Current If

1000mA

Data Transmission Distance

30ft

Wavelength Typ

660nm

Msl

MSL 4 - 72 Hours

Fiber Material

Plastic

Leaded Process Compatible

Yes

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Applications

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

For Use With

Plastic Optical Fiber

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-2062

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

HFBR-2521Z

Manufacturer:

AVAGO/安华高

Quantity:

20 000

Handling

Versatile Link components are auto-insertable. When

wave soldering is performed with Versatile Link compo-

nents, the optical port plug should be left in to prevent

contamination of the port. Do not use reflow solder

processes (i.e., infrared reflow or vapor-phase reflow).

Nonhalogenated water soluble fluxes (i.e., 0% chloride),

not rosin based fluxes, are recom mended for use with

Versatile Link components.

Versatile Link components are moisture sensitive

devices and are shipped in a moisture sealed bag. If the

components are exposed to air for an extended period

of time, they may require a baking step before the solder-

ing process. Refer to the special labeling on the shipping

tube for details.

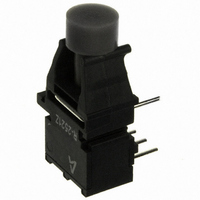

Mechanical Dimensions

Horizontal Modules

3

(0.025)

(0.109)

(0.080)

0.64

2.77

2.03

(0.300)

7.62

1. Shelf life in sealed bag: 12 months at < 40°C and < 90% Relative Humidity (RH).

2. After this bag is opened, devices that will be subjected to wave soldering, or

3. Devices require baking, before mounting, if:

4. If baking is required, devices may be baked outside of tube for 20 hours at 75°C.

Bag Seal Date: ______________________________________________________

Note: LEVEL defined by EIA JEDEC Standard J-STD-020

equivalent processing (solder temperature < 260°C for 10 sec) must be:

a) Mounted within 72 hours at factory conditions of ≤ 30°C/60% RH.

b) Stored at ≤ 20% RH.

a) Desiccant changes to PINK.

b) If 2a or 2b are not met.

(0.74)

18.8

(0.073)

1.85

This bag contains

MOISTURE-SENSITIVE

0.64 (0.025) DIA.

(If blank, see barcode label)

3.81 (0.150) MAX.

3.56 (0.140) MIN.

CAUTION

DEVICES

(0.270)

6.86

(0.30)

7.62

(0.020)

0.51

Level

4

(0.400)

10.16

(0.200)

(0.100)

5.08

2.54

(0.050)

1.27

(0.165)

4.19

Recommended Chemicals for Cleaning/Degreasing

Alcohols: methyl, isopropyl, isobutyl. Aliphatics: hexane,

heptane. Other: soap solution, naphtha.

Do not use partially halogenated hydrocarbons such

as 1,1.1 trichloroethane, ketones such as MEK, acetone,

chloroform, ethyl acetate, methylene dichloride, phenol,

methylene chloride, or N-methylpyrolldone. Also, Avago

does not recommend the use of cleaners that use

halogenated hydrocarbons because of their potential

environmental harm.

Vertical Modules

(0.080)

2.03

(0.400)

10.16

(0.27)

6.86

(0.200)

(0.740)

18.80

5.08

(0.720)

18.29