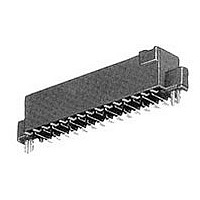

104652-1 TE Connectivity, 104652-1 Datasheet - Page 4

104652-1

Manufacturer Part Number

104652-1

Description

Manufacturer

TE Connectivity

Specifications of 104652-1

Connector Type

Connector Assembly

Mount Angle

Vertical

Pcb Mount Retention

With

Mating Connector Lock

Without

Hold-down Post Material

Copper Alloy

Hold-down Post Plating

Tin-Lead (150) over Nickel (50)

Insulation Resistance (m?)

5,000

Voltage (vac)

30

Dielectric Withstanding Voltage (v)

300

Contact - Rated Current (a)

1 – 4

Solder Tail Contact Plating

Tin-Lead (150)

Number Of Positions

10

Pcb Mount Retention Type

Hold Down Post(s)

Contact Base Material

Copper Alloy

Contact Plating, Mating Area, Material

Gold (30)

Underplate Material

Nickel

Connector Style

Receptacle

Mating Alignment

With

Mating Alignment Type

Polarizing Tab

Housing Material

Thermoplastic - GF

Ul Flammability Rating

UL 94V-0

Housing Color

Black

Rohs/elv Compliance

ELV compliant, 5 of 6 Compliant

Lead Free Solder Processes

Reflow solder capable to 245°C, Reflow solder capable to 260°C

Approved Standards

UL E28476, CSA LR7189

Temperature Range (°c)

-65 – +105

Packaging Method

Tube

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

104652-1

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

62

3.6.

Mixed flowing gas.

Mixed flowing gas.

Rev C

NOTE

Product Qualification and Requalification Test Sequence

Test Description

Shall meet visual requirements, show no physical damage and shall meet requirements of

additional tests as specified in Test Sequence in Figure 2.

NOTE

(a)

(b)

(c)

(d)

Examination of product

Termination resistance

Insulation resistance

Dielectric withstanding voltage

Temperature rise vs current

Vibration

Physical shock

Durability

Contact retention

Mating force

Unmating force

Thermal shock

Humidity-temperature cycling

Temperature life

Mixed flowing gas, Class III

Mixed flowing gas, Class IIIA

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Discontinuities shall not be measured. Energize at 18

per Quality Specification 102-950.

Precondition specimens with 10 cycles durability.

Test or Examination

See Note.

See Note.

Figure 1 (end)

Requirement

Figure 2

1,9

3,7

1

5

6

4

2

8

Test Sequence (b)

Test Group (a)

6(c)

4(d)

4(d)

1,9

2,7

3,8

2

5

1,8

2,6

3,7

EIA-364-65, Class III (3 gas).

Subject mated beryllium copper

specimens to environmental class

III for 20 days.

EIA-364-65, Class IIIA (4 gas).

Subject mated copper alloy

specimens to environmental Class

IIIA for 20 days.

3

4

5

1,3

4

2

E

C level for 100% loadings

Procedure

108-1332

4 of 7