EP3C55F484I7 Altera, EP3C55F484I7 Datasheet - Page 40

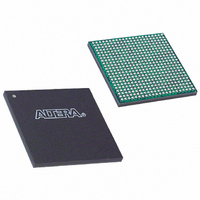

EP3C55F484I7

Manufacturer Part Number

EP3C55F484I7

Description

IC CYCLONE III FPGA 55K 484 FBGA

Manufacturer

Altera

Series

Cyclone® IIIr

Datasheets

1.EP3C5F256C8N.pdf

(5 pages)

2.EP3C5F256C8N.pdf

(34 pages)

3.EP3C5F256C8N.pdf

(66 pages)

4.EP3C5F256C8N.pdf

(14 pages)

5.EP3C5F256C8N.pdf

(76 pages)

Specifications of EP3C55F484I7

Number Of Logic Elements/cells

55856

Number Of Labs/clbs

3491

Total Ram Bits

2396160

Number Of I /o

327

Voltage - Supply

1.15 V ~ 1.25 V

Mounting Type

Surface Mount

Operating Temperature

-40°C ~ 100°C

Package / Case

484-FBGA

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Number Of Gates

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

EP3C55F484I7

Manufacturer:

TI

Quantity:

2 847

Company:

Part Number:

EP3C55F484I7N

Manufacturer:

FREESCALE

Quantity:

1 445

Company:

Part Number:

EP3C55F484I7N

Manufacturer:

ALTERA

Quantity:

118

Part Number:

EP3C55F484I7N

Manufacturer:

ALTERA/阿尔特拉

Quantity:

20 000

Page 40

Design and Compilation

Pin-Related Assignments

Selectable I/O capabilities increase the flexibility of Cyclone III devices to connect to

other devices in many low-cost applications. Integration of various I/O-related

features further reduces the cost of any application with Cyclone III devices. Notable

features include current strength control, slew rate control, open-drain, bus hold, PCI

clamp diode, weak pull-up, series on-chip termination, and dedicated output buffer

with programmable pre-emphasis. The following sub-sections discuss the

considerations involved when you use some of the features.

f

For more information about each I/O features, refer to the

Cyclone III Device I/O

Features

chapter in volume 1 of the Cyclone III Device Handbook.

Current Strength and Slew Rate Control

Each I/O standard supports a range of programmable current strength. Select a

suitable current strength setting to meet the performance target for your I/O. Note

that higher current strength increases not just I/O performance, but also noise on the

interface. Ensure that the output buffer current strength is sufficiently high without

causing excessive overshoot or undershoot that violates voltage threshold parameters

for the I/O standard. At the same time, the setting should not be too low to cause

stair-step response, which increases edge rate significantly and results in incorrect

clocking if the pin is used as a clock source.

1

Run simulation with Cyclone III IBIS models to determine if your current strength

setting meets the desired performance and the receiver’s input specification.

Cyclone III devices observe a maximum AC voltage of 4.1 V on all the inputs. To

ensure the device reliability, maximum voltage overshoot seen at the Cyclone III

receiver should not exceed the specification. For more details, refer to

AN 447:

Interfacing Cyclone III Devices with 3.3/3.0/2.5-V LVTTL/LVCMOS I/O Systems.

If a large data bus is used in which pins may switch simultaneously, Altera

recommends turning on the slew rate control to reduce simultaneous switching

output (SSO) effects such as crosstalk and ground bounce. Slew rate control is only

available in single-ended I/O standards with 8 mA current strength or higher.

Series On-Chip Termination

Series On-Chip Termination (OCT) in Cyclone III devices can be implemented in two

ways; OCT without calibration, and OCT with calibration. Selection factor is mainly

driven by driver impedance accuracy versus cost of additional external components.

OCT without calibration uses driver output capabilities to match its impedance to the

impedance of the transmission line. For higher impedance matching accuracy,

implement OCT with calibration, which takes into account the voltage and

temperature variation. The calibration process starts at the end of configuration and

completes before user mode operation. While providing better accuracy, you must

Ω

Ω

connect two external resistors of 25

±1% or 50

±1% to a pair of R

and R

pins

UP

DN

for the calibration block. A calibration block is available on each side of the device.

Ω

Ω

Calibration to other impedance values other than the recommended 25

or 50

is

possible, which is limited only by range of buffer impedance.

© November 2008 Altera Corporation