212013-1 TE Connectivity, 212013-1 Datasheet - Page 3

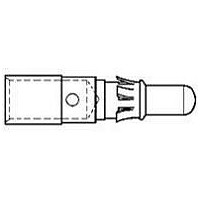

212013-1

Manufacturer Part Number

212013-1

Description

D SUB CONTACT, PIN, 18-16AWG, CRIMP

Manufacturer

TE Connectivity

Series

AMPLIMITE 109r

Specifications of 212013-1

Contact Plating

Gold

Contact Material

Copper Alloy

Wire Size (awg)

18-16

Contact Termination

Crimp

Contact Type

Power

Contact Size

8

Connector Type

Contact, Crimp

Rohs Compliant

Yes

Contact Gender

Pin

Product

Contacts

Shell Plating

Gold

Gender

Male

Mounting Style

Wire

Termination Style

Crimp

Features

Contact

Insulation

Not Insulated

Wire Gauge Range

18-16

Product Type

Contact

Product Series

109

Termination Method To Wire/cable

Crimp

High Current

No

Wire Range (mm [awg])

0.80-1.40² [18-16]

Retention Clip Material

Beryllium Copper

Contact Style

Power

Contact Base Material

Copper Alloy

Contact Plating, Mating Area, Material

Gold (50)

Density

Standard

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Nasa Qualification

No

Applies To

Wire/Cable

Packaging Method

Loose Piece

Lead Free Status / Rohs Status

Details

Rev B

Physical shock.

Durability.

Contact retention.

Mating force.

Unm ating force.

Therm al shock.

Hum idity-tem perature cycling.

Tem perature life.

Mixed flowing gas.

NOTE

Test Description

Shall meet visual requirements, show no physical damage and shall meet requirements of

additional tests as specified in Test Sequence in Figure 2.

No discontinuities of 1 m icrosecond

or longer duration.

See Note.

See Note.

Contacts shall not dislodge.

80 ounces m axim um initial per

contact.

5 ounces m inim um initial per

contact.

See Note.

See Note.

See Note.

See Note.

ENVIRONMENTAL

Figure 1 (end)

Requirem ent

TE Spec 109-30.

TE Spec 109-26-4,

except 300 G's and 3 m illiseconds.

Subject m ated sam ples to 300 G's

half-sine shock pulses of 3

m illiseconds duration. 3 shocks in

each direction applied along 3

m utually perpendicular planes, 18

total shocks.

TE Spec 109-27.

Mate and unm ate sam ples for 500

cycles at m axim um rate of 300

cycles per hour.

Apply axial load of 15 pounds to

contacts and hold for 5 seconds.

TE Spec 109-42, Condition A.

Measure force necessary to m ate

sam ples at m axim um rate of .5 inch

per m inute.

TE Spec 109-42, Condition A.

Measure force necessary to

unm ate sam ples at m axim um rate

of .5 inch per m inute.

TE Spec 109-22.

Subject m ated sam ples to 5 cycles

between -55 and 125°C.

TE Spec 109-23-3,

Condition B.

Subject m ated sam ples to 10

cycles between 25 and 65°C at

95% RH.

TE Spec 109-43.

Subject m ated sam ples to

tem perature life at 125°C for 1000

hours.

TE Spec 109-85-2.

Subject m ated sam ples to

environm ental class II for 14 days.

Procedure

108-10045

3 of 6