881593-1 TE Connectivity, 881593-1 Datasheet - Page 6

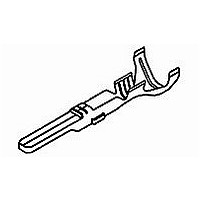

881593-1

Manufacturer Part Number

881593-1

Description

ECONOSEAL TAB .070

Manufacturer

TE Connectivity

Series

070r

Specifications of 881593-1

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

17 – 20

Wire/cable Size (mm²)

0.5 – 1

Profile Height (y-axis) (mm [in])

0.64 [0.025]

Wire Type

Stranded

Length (x-axis) (mm [in])

20.40 [0.8031]

Width (z-axis) (mm [in])

1.80 [0.0708]

Contact Type

Tab

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

1.40 – 2.40 [0.055 – 0.094]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Housing Ass’y 6p Rec. & Tab Hybrid Jr. Power Timer / Multi Lock

Revisão “B”

4.5.12

4.5.13

4.5.14

4.5.15

4.5.16

4.5.17

4.5.18

4.5.19

ITEM

Connector to Connector

Connector Polarization

Disengagement Force

Disengagement Force

Un-Locked Connector

Feature Effectiveness

Isolation Resistance

Engagement Force

Locked Connector

Dielectric Strength

Terminal Position

Flammability

Assurance

TEST

CONNECTOR SYSTEM MECHANICAL TESTS

when tested according to GMW 3232 shall be

occur between cavities at any time during the

occur between the cavities and the outside of

TPA closing force with correct assembled

Damages do not have to occur that harm a

No dielectric breakdown or flash-over shall

No dielectric breakdown or flash-over shall

The burn rate of the material test samples

Electric continuity does not have to occur;

TPA closing force with one improperly

partially inserted terminal shall be greater

The closing force with one improperly or

a connector at any time during the test.

It does not have to allow assembly;

(with all the inserted terminals).

than 60 N for all terminal sizes.

12,5N minimum Hsg assy rec;

20N minimum Hsg assy tab.

17N minimum Hsg assy rec;

25N minimum Hsg assy tab.

Closed TPA locking force:

100 Mega-Ohms minimum.

less than 100 mm/min.

TPA Pre-Lock Force:

inserted terminal:

REQUIREMENTS

correct assembly.

100N maximum.

100N minimum.

30N maximum.

75N maximum.

terminals:

test;

terminal in housing with

terminal in housing with

in housing with a speed

samples during 3 to 23

500VDC / 15 seconds.

in all the ways, guiding

female, with terminals

them in incorrect way.

To extraction the TPA

rate of 50 10mm/min

connectors male and

together at a uniform

of 50±10mm/minute.

until fully seated and

flammability test per

1000Vac / 1 minute.

To try to mount the

To apply a force of

50±10mm/minute.

50±10mm/minute.

between 45-70%;

To extraction the

To extraction the

Mate connectors

hours ±5ºC, with

To condition the

relative humidity

PROCEDURES

Perform the

GMW 3232

a speed of

a speed of

locked.

150N.

108-37083

6 de 8