881593-1 TE Connectivity, 881593-1 Datasheet - Page 4

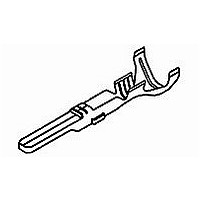

881593-1

Manufacturer Part Number

881593-1

Description

ECONOSEAL TAB .070

Manufacturer

TE Connectivity

Series

070r

Specifications of 881593-1

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

17 – 20

Wire/cable Size (mm²)

0.5 – 1

Profile Height (y-axis) (mm [in])

0.64 [0.025]

Wire Type

Stranded

Length (x-axis) (mm [in])

20.40 [0.8031]

Width (z-axis) (mm [in])

1.80 [0.0708]

Contact Type

Tab

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

1.40 – 2.40 [0.055 – 0.094]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Housing Ass’y 6p Rec. & Tab Hybrid Jr. Power Timer / Multi Lock

Revisão “B”

ITEM

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.5

Dry Circuit Resistance

Visual Examination

Mechanical Shock

Connector and/or

Terminal Cycling

Heavy Duty Test

Test Requirements and Procedures Summary

Vibration

TEST

CONNECTOR ELECTRICAL TESTS

entire Mechanical Shock and Vibration with

There shall be no corrosion, discoloration,

Ohms for longer than 1µs, throughout the

tolerances specified on the part drawing.

metal apparent at the contact surface, or

temperature of +23 ± 5 ° C for at least 24

completion of the Vibration with Thermal

continuity, i.e., resistance greater than 7

For terminal size ≤2,8mm Junior Power

For terminal size ≤2,8mm Junior Power

physical distortion shall not exceed the

viewed under 10 to 40X magnification.

Test samples shall not have any base

t

For terminal size ≤1,5mm Multi Lock:

For terminal size ≤1,5mm Multi Lock:

functionality of the part. Swelling or

evidence of fretting corrosion, when

cracks, etc., which could affect the

of 50ºC maximum, during each cycle;

There shall be no loss of electrical

Store test samples at an ambient

Samples are evaluated only after

Timer: 5,0m , maximum.

Timer: 5,0m , maximum;

Thermal Cycling Tests;

Discontinued ≤7 /1µs;

15,0m , maximum;

8,0m , maximum;

REQUIREMENTS

Cycling Test.

Table 2

Item 4.5.1;

Item 4.5.3.

Item 4.5.1;

hours.

and functionally inspected

Acceleration (g) - Number

Acceleration (g) - Number

schedule" (acceleration of

20,9m/s² RMS) – duration

5 cycles: 5 hours of 80ºC,

or terminal pair 10 times.

discontinuities during the

(positive and negative) =

limits the current applied

resistance low level (dry

unmate each connector

circuit) before and after

Micro-ohmmeter which

(positive and negative)

Lock size 2,5mm²; and

To apply the profiles of

+85 a -40ºC in cycle of

Visually, dimensionally

Body (sprung masses)

Completely mate and

voltage to 20 mV and

14A for terminal Multi

per applicable quality

limits the open circuit

22,5A for terminal Jr.

5 cycles: 2 hours of -

Measure the contact

of shocks per axis,

of shocks per axis,

Power Timer size

40ºC, off current.

random vibration

Test Nº. 02: 100

PROCEDURES

inspection plan.

Test Nº. 01: 25

vibration and

temperature;

Monitoring of

480 minute.

to 100 mA.

Item 4.5.1;

the assay;

24h/eixo;

4,0mm².

assay;

= 18.

792;

108-37083

4 de 8