2058302-1 TE Connectivity, 2058302-1 Datasheet - Page 7

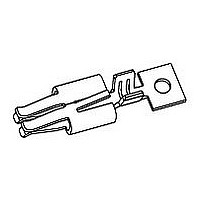

2058302-1

Manufacturer Part Number

2058302-1

Description

SOCKET CONTACT

Manufacturer

TE Connectivity

Datasheet

1.1-2058703-1.pdf

(8 pages)

Specifications of 2058302-1

Connector Type

Contact, Crimp

Current Rating

5A

Contact Plating

Tin

Contact Material

Copper Alloy

Contact Size

18

Contact Gender

Socket

Contact

RoHS Compliant

Contact Termination

Crimp

Rohs Compliant

Yes

Product

Blade Terminals

Wire Size (awg)

22-18

Insulation

Not Insulated

Gender

Male

Termination Style

Crimp

Mounting Angle

Straight

Mounting Method

Wire

Number Of Positions / Contacts

1

Number Of Rows

1

Voltage Rating

125 V

Product Type

Contact

Wire/cable Type

Discrete Wire

Termination Method To Wire/cable

Crimp

Keyed

No

Make First / Break Last

No

Contact Current Rating, Max (a)

5

Wire/cable Size (awg)

18 – 22

Profile Height (y-axis) (mm [in])

3.00 [0.118]

Length (x-axis) (mm [in])

11.90 [0.468]

Width (z-axis) (mm [in])

4.70 [0.185]

Contact Type

Socket

Contact Plating, Mating Area, Material

Matte Tin

Stamped And Formed

Yes

Pre-designed Cables Available

Yes

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Circuit Identification Feature

Without

Applies To

Wire/Cable

Glow Wire Rating

No

Uv Exposure Rated

No

Application Use

Wire-to-Board

Packaging Method

Strip

For Use With

Hermaphroditic Wire-to-Board

Lead Free Status / Rohs Status

Details

5.1. Hand Crimping Tools

Hand crimping tools that accommodate the full wire size range are designed for prototype and low volume

applications.

5.2. Applicators

Applicators are designed for the full wire size range of strip--fed, precision formed contacts, and provide for

high volume, heavy duty production requirements. The applicators can be used in bench or floor model power

units. See Figure 8.

5.3. Power Units

A power unit is an automatic or semi--automatic machine used to assist in the application of a product. Power

units provide the force required to drive the applicator. See Figure 8.

5.4. Extraction Tools

Extraction tools are designed to release the locking lance inside the connector housing without damaging the

housing or contacts. Customers may use their own extraction tools, in which case the tool must fit in a

1.10 x 0.70 mm opening in the housing. The tool must be long enough to release the locking lance which is

located at a depth of 10.50 mm in the housing.

Rev E

Heavy Duty Mini (HDM)

Side Feed Applicator

NOTE

NOTE

i

i

SIZE (AWG)

22

20

18

TE Tool Engineers have designed machines for a variety of application requirements. For assistance in setting up

prototype and production line equipment, contact TE Tool Engineering through your local TE Representative, or call

the Tooling Assistance Center number at the bottom of page 1.

Each applicator is shipped with a metal identification tag attached. DO NOT remove this tag or disregard the

information on it. Also, a packet of associated paperwork is included in each applicator shipment. This information

should be read before using the applicator; then it should be stored in a clean, dry area near the applicator for future

reference. Some changes may have to be made to the applicators to run in all related power units. Contact the Tooling

Assistance Center number located at the bottom of page 1 for specific changes.

WIRE

INSULATION DIA.

1.65--2.03

1.65--2.03

1.65--2.03

1852817--3 (408--8040)

85 8

APPLICATOR

Figure 8

3 ( 08 80 0)

PRO- - CRIMPER III

Hand Tool Assembly

2063778- - 1 with Die

Assembly 2063778- - 2

AMP- - O- - LECTRIC

Model “G” Terminating

Machine 354500- - [ ]

TOOLING (DOCUMENT)

354500--1 (409--5842)

35 500

POWER UNIT

( 09 58 )

2063778--1 (408--10290)

063 8

HAND TOOL

( 08 0 90)

114- 13252

7 of 8