2-1705300-1 TE Connectivity, 2-1705300-1 Datasheet - Page 75

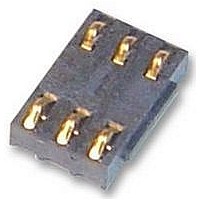

2-1705300-1

Manufacturer Part Number

2-1705300-1

Description

CONNECTOR, SIM, 2.1MM

Manufacturer

TE Connectivity

Type

SIMr

Datasheet

1.SRP175L.pdf

(116 pages)

Specifications of 2-1705300-1

Gender

M

Mounting Style

Surface Mount

Termination Method

Solder

Body Orientation

Straight

Contact Pitch (mm)

2.54mm

Housing Material

Thermoplastic

Number Of Contact Rows

2

Number Of Contacts

6POS

Contact Material

Copper Alloy

Connector Type

SIM Socket

Row Pitch

7.3mm

Pitch Spacing

2.54mm

No. Of Contacts

6

Contact Termination

Surface Mount Vertical

No. Of Rows

2

Contact Plating

Gold Over Nickel

Rohs Compliant

Yes

Svhc

No

Product Type

Connector

Card Type

2FF mini SIM

Card Guide Slots

Without

Pcb Mount Style

Surface Mount

Contact Retention

No

Connector Stabilization Ribs

Without

Height Above Pc Board (mm [in])

2.10 [0.083]

Card Stop

Without

Ejector Type

Push - Pull

Centerline (mm [in])

2.54 [0.100]

Durability Rating

5000 Cycles

Contact Base Material

Selective Gold

Housing Color

Black

Ul Flammability Rating

UL 94V-0

Card Insertion Style

Normal Insertion

Card Detection Switch

Without

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Reflow solder capable to 245°C, Reflow solder capable to 260°C

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Tape & Reel

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

2-1705300-1

Manufacturer:

TYCO

Quantity:

14 050

Mechatronic Center

Niefern

Advanced Tyco Electronics

technologies allow us to

produce highly competitive

semi-finished products for

card manufacturers of the

1

■

■

■

■

The products are delivered

on a reel and can be used

for chip mounting by our

customers.

st

, 2

High-Speed Stamping

Selective Plating

Laminating

Reel-to-Reel Over-Molding

nd

and 3

rd

generation.

Products for Mobile Equipment

Mechatronic Center Niefern

Technology Portfolio

All specifications subject to change. Consult Tyco Electronics for latest specifications.

Reel-to-Reel

Over-Molding

■

■

Free cutting in line

Multiple cavities

mold

Reel-to-Reel Stamping

■

■

■

Reel-to-Reel Plating

■

■

■

Reel-to-Reel Lamination

■

■

■

■

■

Bonding Capability Guaranty

High-speed stamping

4 fold stamping tool,

70 mm width

Material: Copper alloy

Plating in 70 mm width

Selective Metalization:

●

●

●

Slitting in 35 mm

Clean room class 100,000

High accuracy dielectric

stamping

Mechanical alignment and

prefixing of dielectric

Leadframe roll lamination

100 % video control

Overall Ni

Contacts Side:

– Spots on contact area

– Gold flash

Bonding Side:

– Strips or Spots

Catalog 1654270-2

Revised 8-2007

73