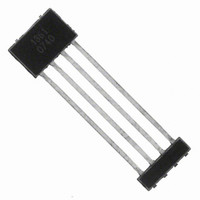

A1361LKTTN-T Allegro Microsystems Inc, A1361LKTTN-T Datasheet - Page 23

A1361LKTTN-T

Manufacturer Part Number

A1361LKTTN-T

Description

IC,HALL-EFFECT SENSOR,SINGLE-ENDED,BICMOS,SIP,4PIN,PLASTIC

Manufacturer

Allegro Microsystems Inc

Type

Linear - Unipolar, Bipolarr

Datasheet

1.A1360LKTTN-T.pdf

(25 pages)

Specifications of A1361LKTTN-T

Sensing Range

1.4mV/G ~ 4.5mV/G

Voltage - Supply

4.5 V ~ 5.5 V

Current - Supply

12mA

Current - Output (max)

10mA

Output Type

Analog, Ratiometric

Features

Programmable

Operating Temperature

-40°C ~ 150°C

Package / Case

4-SIP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

620-1234-2

A1360, A1361,

and A1362

Figure 8. The flux density per ampere measured by the A136x Hall sen-

sor IC is related to the core gap, as shown. This figure assumes that the

current sensing application is constructed using the example setup.

14

12

10

8

6

4

2

0

0.5

Flux Density per Ampere vs. Gap for a Feedthrough Sensor

1

Wire

1.5

+B

Figure 9. Side view of example current-conducting wire and split ring concentrator (left), and

magnetic profi le (right) through the midplane of the gap in the split ring concentrator. The fl ux

denisty through the center of the gap varies between the inside and the outside of the gap.

–2

Gap (mm)

mm

0

Ring concentrator

Adjustable Bandwidth (50 kHz Maximum) and Analog Output

2

Low-Noise Programmable Linear Hall Effect Sensor ICs with

2

Magnetic flux in gap

Measurement plane

(midplane of gap)

2.5

3

3.5

The flux density measured by the A136x SIP is related to the

size of the gap cut into the core. The larger the gap in the core,

the smaller the flux density per ampere of applied current (see

figure 8).

Figure 9 depicts the magnetic flux density through the center of

the SIP as a function of SIP to core alignment. Note that a core

with a larger cross-sectional area would reduce the attenuation

in flux density that results from any SIP misalignment. The flat

portion of the curve in figure 9 would span a larger distance in

millimeters if the cross-sectional area of the core were increased.

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

–2.0

Radial Displacement from Concentrator Centerline (mm)

Interior side of

Concentrator

–1.0

115 Northeast Cutoff

1.508.853.5000; www.allegromicro.com

Allegro MicroSystems, Inc.

Worcester, Massachusetts 01615-0036 U.S.A.

0

Exterior side of

Concentrator

1.0

2.0

23