HFBR-0566 Avago Technologies US Inc., HFBR-0566 Datasheet - Page 9

HFBR-0566

Manufacturer Part Number

HFBR-0566

Description

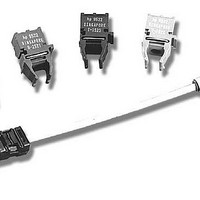

Fiber Optic Development Tools MT-RJ 622Mb/s Fast E Evaluation Kit

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HFBR-0566.pdf

(17 pages)

Specifications of HFBR-0566

Description/function

Fiber Optic Kit

For Use With/related Products

HFBR-5908E, HFCT-5908E

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Electromagnetic Interference (EMI)

One of a circuit board designer’s foremost concerns is

the control of electromagnetic emissions from electronic

equipment. Success in controlling generated Electromag-

netic Interference (EMI) enables the designer to pass a

governmental agency’s EMI regulatory standard and more

importantly, it reduces the possibility of interference to

neighboring equipment. Avago has designed the HFBR/

HFCT-5908E to provide excellent EMI performance. The EMI

performance of a chassis is dependent on physical design

and features which help improve EMI suppression. Avago

encourages using standard RF suppression practices and

avoiding poorly EMI-sealed enclosures.

Radiated Emissions for the HFBR/HFCT-5908E have been

tested successfully in several environments. While this

number is important for system designers in terms of

emissions levels inside a system, Avago recognizes that

the performance of most interest to our customers is the

emissions levels, which could be expected to radiate to

the outside world from inside a typical system. In their

application, SFF transceivers are intended for use inside an

enclosed system, protruding through the specified panel

opening at the specified protrusion depth.

Along with the system advantage of high port density

comes the increase in the number of apertures. Careful

attention must be paid to the locations of high-speed

clocks or gigabit circuitry with respect to these apertures.

While experimental measurements and experiences do not

indicate any specific transceiver emissions issues, Avago

recognizes that the transceiver aperture is often a weak

link in system enclosure integrity and has designed the

modules to minimize emissions and contain the internal

system emissions by shielding the aperture.

To that end, Avago’s OC-12/STM-4 MT-RJ transceivers

(HFCT-5908E and HFBR-5908E) have nose shields which

provide a convenient chassis connection to the nose of

the transceiver. This nose shield improves system EMI

performance by closing off the MT-RJ aperture. Localized

shielding is also improved by tying the four metal housing

package grounding tabs to signal ground on the PCB.

Though not obvious by inspection, the nose shield and

metal housing are electrically separated for customers

who do not wish to directly tie chassis and signal grounds

together. The recommended transceiver position, PCB

layout and panel opening for both HFBR/HFCT-5908E are

the same, making them mechanically drop-in compatible.

Figure 7 shows the recommended positioning of the trans-

ceivers with respect to the PCB and faceplate.

9

Package and Handling Instructions

Flammability

The HFBR/HFCT-5908E transceiver housing consists of high

strength, heat resistant, chemically resistant, and UL 94 V-0

flame retardant plastic and metal packaging.

Recommended Solder and Wash Process

The HFBR/HFCT-5908E is compatible with industry-

standard wave or hand solder processes.

Process plug

This transceiver is supplied with a process plug for protec-

tion of the optical port within the MT-RJ connector recep-

tacle. This process plug prevents contamination during

wave solder and aqueous rinse as well as during handling,

shipping and storage. It is made of a high-temperature,

molded sealing material that can withstand +80°C and a

rinse pressure of 110 lbs per square inch.

Recommended Solder fluxes

Solder fluxes used with the HFBR/HFCT-5908E should be

water-soluble, organic fluxes. Recommended solder fluxes

include Lonco 3355-11 from London Chemical West, Inc.

of Burbank, CA, and 100 Flux from Alpha-Metals of Jersey

City, NJ.

Recommended Cleaning/ Degreasing Chemicals

Alcohols: methyl, isopropyl, isobutyl.

Aliphatics: hexane, heptane

Other: naphtha.

D o not use p a r t i a l l y h a l o g e n a t e d hy d ro c a r -

bons such as 1,1.1 tr ichloroethane, ketones

such as MEK, acetone, chloroform, ethyl acetate,

methylene dichloride, phenol, methylene chloride, or

N-methylpyrolldone. Also, Avago does not recommend

the use of cleaners that use halogenated hydrocarbons

because of their potential environmental harm.