1981568-1 TE Connectivity, 1981568-1 Datasheet - Page 74

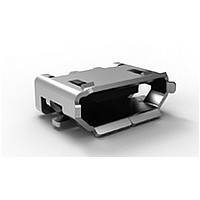

1981568-1

Manufacturer Part Number

1981568-1

Description

REC TYPE B ASSY (AU) MICRO USB

Manufacturer

TE Connectivity

Series

DisplayPort Receptacles and Cable Assembliesr

Datasheet

1.1981568-1.pdf

(116 pages)

Specifications of 1981568-1

Number Of Contacts

5POS

Body Orientation

Right Angle

Contact Material

Copper Alloy

Operating Temp Range

-55C to 85C

Current Rating (max)

1/ContactA

Voltage Rating Max

30VAC

Product Height (mm)

3mm

Number Of Ports

1Port

Gender

RCP

Mounting Style

Surface Mount

Contact Plating

Gold Over Nickel

Housing Material

Thermoplastic

Product

Micro USB Type B Connectors

Standard

USB

Pitch

0.65 mm

Current Rating

1 A

Termination Style

Solder Pad

Connector Type

Micro USB Type B Receptacle

Color

Black

Features

Without Locking Feature

Flammability Rating

UL 94 V-0

Insulation Resistance

100 MOhms

Mounting Angle

Right

Number Of Positions / Contacts

5

Operating Temperature Range

0 C to + 50 C

Voltage Rating

30 VAC

Size

Micro

Orientation

Right Angle

Mount Location

Top

Termination Method

Surface Mount

Locking Feature

Without

Led

Without

Panel Ground

Without

Pcb Mount Retention Type

SMT Hold Down

Shell Plating

Reflowed Tin over Nickel

Assembly Process Feature

Without Pick and Place Cover

Locating Post(s)

Without

Number Of Positions

5

Contact Termination Type

Surface Mount

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Housing Color

Black

Industry Standard

USB 2.0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Reflow solder capable to 245°C

Rohs/elv Compliance History

Always was RoHS compliant

Usb-if Test Id Number (tid)

60001336

Applies To

Printed Circuit Board

Pcb Thickness, Recommended (mm [in])

1.00 [0.039]

Packaging Method

Tape & Reel

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1981568-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

1981568-1

Manufacturer:

TE

Quantity:

20 000

72

Products for Mobile Equipment

Batteries

Battery Systems

Core Manufacturing Processes

Cost effective and flexible manufacturing methods are at the core of TEBS’ working methodology.

Incorporating advanced production techniques and the most reliable and efficient equipment

available in both manual and automated processes. TEBS’ production techniques ensure the

consistency and high performance of the finished product.

Flexible, future proof processes allow large volume manufacturing capacities and a higher degree

of repeatability in both quality and quantity of products. Integrating the best in both design and

assembly, TEBS gives you a world-class combination in both service and technology.

Testing and Qualification

With a fully integrated professional battery pack and cell testing facility in Shanghai, China,

TEBS provides complete in-house component and battery pack approval, typically covering cell,

PCB and full product assemblies. Testing includes pre-compliance and planned compliance

testing in safety, abuse, EMC, environmental reliability, performance and life testing through

internal, customer and regulatory specifications and standards.

In Shanghai, an array of environmental chambers, cell and pack cycling channels and other

specialized equipment is housed in over 6,000 square feet of dedicated testing space. These

unique independent testing capabilities offer our customers the ability to complete all of their

required specification and environmental testing under one roof and enables TEBS to offer the

complete turnkey power solution.

The lab is approved by UL to conduct UL1642 and UL2054 testing and issue certification to

both standards. TEBS also has senior level representation on the UL Standards Technical Panel

(UL1642 & UL2054) and IEEE-P1725 Work Group. TEBS has the additional capability to conduct

all UN/DoT testing in-house and provide the required certification documents.

All specifications subject to change. Consult Tyco Electronics for latest specifications.

Global Commitment

TEBS’ world-wide engineering design team

incorporates electrical, mechanical and chemical

expertise to shorten the time required for design

and development, ultimately reducing product

delivery times. Our cutting edge technology can

increase functionality while reducing size, weight

and cost.

TEBS has the ability to offer a turnkey design

and manufacturing solution to match the battery

system to the specifications of your products.

Our unique program management system gives

you a champion inside TEBS, charged with

supervising the design process from concept

through finished product.

When you specify TEBS, you are buying the

power to bring innovations to market, on time.

Catalog 1654270-2

Revised 8-2007