500-702 MEGA, 500-702 Datasheet - Page 4

500-702

Manufacturer Part Number

500-702

Description

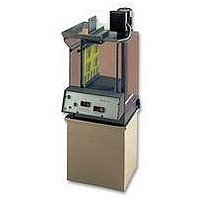

SPRAY PROCESSOR, ROTA-SPRAY

Manufacturer

MEGA

Type

Processing Equipmentr

Datasheet

1.500-702.pdf

(5 pages)

Specifications of 500-702

External Height

650mm

External Width

475mm

Svhc

No SVHC (15-Dec-2010)

External Depth

500mm

External Length / Height

650mm

Heavy Product

1

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

PROCEDURE

1. Push the P key.

2. The LED OUT will blink.

3. Press the UP key to increase the time.

4. Press the DOWN key to decrease the time.

5. Not pressing any key for 5 seconds will automatically leave set time mode

.

Board Holder

The board holder enables the operator to move the PCB laminate into a separate integral

spray wash tank for cleaning without coming into contact with the chemistry.

It maybe loaded with a 10” x 12” panel or several smaller panels using the additional board

holder rails. To add extra rails, undo the nuts and remove the bottom of the board holder,

slide in extra rails and re-assemble. All panels on one rail should be identical in at least

one dimension so they are parallel to the rails. This way, they will remain secure. The

panel(s) are best loaded with the board holder in a vertical position. Standard 1.6mm thick

P.C.B’s and Metal Panels are best retained, using the ‘V’ grooves. The top and bottom rails

can be reversed to hold up to 3mm thick panels in ‘Square’ grooves.

**

NOTE: Use the board holder key provided to tighten and undo the nuts. Apply enough

torque to secure the rails in place.

Avoid over-tightening as this may damage some

components.

Processing

When the time is Set and the Pre-set temperature reached, the unit is ready to process.

Insert the loaded board holder in the unit and secure the lid. Turn ON the timer to operate

the motor. After processing, you can examine the panel(s) whilst they are still in the unit.

If necessary, the unit can be re-activated for additional spray processing. The Start / Stop

can be used to achieve this without re-setting the timer. After processing has finished it is

best to lift the loaded board holder. Slowly and carefully upwards and let any liquid drain

into the processing chamber before putting it into the wash chamber.

Spray Wash

Switch ON the spray wash switch on the Control Panel, which will open a solenoid valve

and allow water to pass through the spray wash bars. Then gently lower the board holder

into the Spray Wash Chamber. Ensure the board holder and panel(s) are completely clean

before switching off, and removing the panels.

Emptying Process Chamber

The process chamber drain outlet is fitted with a threaded plug to avoid accidental spillage,

should the drain valve be tampered with.

The drain valve handle must be in a vertical position to close the valve.

To drain the unit, first ensure the valve is in the closed position, using a suitable wrench.

Unscrew the threaded plug and fit the drain hose assembly. Empty the contents of the unit

into a suitable container by turning the valve through 90º into the ‘Open’ position.

Before refilling the chamber, close the drain valve, remove drain hose assembly and refit

threaded plug

DO NOT OVER TIGHTEN THE THREADED PLUG AS THIS COULD CAUSE

DAMAGE TO THE VALVE ASSEMBLY.

For extra security against tampering – the handle of the drain valve can be removed by

gently pulling it away from the valve shaft.