500-702 MEGA, 500-702 Datasheet - Page 3

500-702

Manufacturer Part Number

500-702

Description

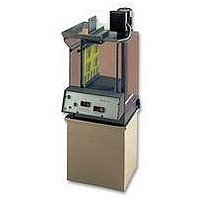

SPRAY PROCESSOR, ROTA-SPRAY

Manufacturer

MEGA

Type

Processing Equipmentr

Datasheet

1.500-702.pdf

(5 pages)

Specifications of 500-702

External Height

650mm

External Width

475mm

Svhc

No SVHC (15-Dec-2010)

External Depth

500mm

External Length / Height

650mm

Heavy Product

1

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Setting temperature mode

Setting the temperature is achieved by programming the set point.

1 – KEY P: Is used to program the set point.

2 – KEY DOWN: Is used to decrease the programming values.

3 – KEY UP: Is used to increase the programming values.

4 – LED OUT/SET: It indicates when the output is ON (light on), OFF (light off) or

if in Programming Mode (blinking rapidly).

Timer operation

The timer is used to operate the motor for set time periods. Once the timer is set and the

START key pressed, the motor operates and the timer counts down to Zero.

The motor will not operate unless the lid is in place.

Setting the timer

1. Push the P key and keep it pushed for one second

2. SP will be displayed and the out/set led will blink rapidly

3. Release the key and the set point will be displayed

4. Press up key to increase temperature

5. Press down key to decrease temperature

6. Not pressing any key for five seconds will automatically leave set temperature

7. The liquid temperature will now be displayed.

figure 3

mode

6. LED OUT 1 : Indicates when the output is ON or OFF

SET

C NT

5

6

5. LED SET / CNT: Signals set point mode (flashing fast),

Count on mode (flashing each second), the count stopped

(on) or reset mode (off).

P

figure 3

STAR T

STOP

P

3

2

1

4

4

3

2

1

figure 2

4. KEY START / STOP Is used to

Start, Stop or Reset the counter.

3. KEY UP: Is used to increase the

programming

2. KEY DOWN: Is used to decrease

the programming values.

1. KEY P: Is used to program the

set point

values