SMB55RA BANNER ENGINEERING, SMB55RA Datasheet - Page 8

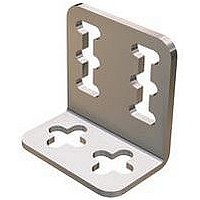

SMB55RA

Manufacturer Part Number

SMB55RA

Description

Sensor Mounting Bracket

Manufacturer

BANNER ENGINEERING

Specifications of SMB55RA

For Use With

R58E Series Expert Register Mark Sensors

Lead Free Status / Rohs Status

RoHS Compliant part

8

R58 Expert

In addition to its configuration function, the remote input may be used to disable the push

buttons for security. Disabling the push buttons prevents unauthorized adjustment of the

configuration settings. Connect the gray wire of the sensor as described on page 3, and four-

pulse to either enable or disable the push buttons (0.04 sec. ≤ “T” ≤ 0.8 sec.):

NOTE: Push buttons can be disabled/enabled from the remote line only.

The R58E includes a total of eight size M5 threaded holes used for mounting (see dimension

drawing on page 11). These threaded holes are positioned to match the mounting hole

patterns common to other registration mark sensors. The R58E includes four M5 x 0.8 x 6 mm

stainless steel cap screws and a hex key wrench.

The R58E focus is 10 mm (0.39") from the lens surface. The R58E must be mounted within 3

mm (0.12") of this distance from the surface of the material for reliable sensing

(Figure 6). Consider the following when mounting the R58E:

• W henever possible, it is a good idea to sense a web material at a location where it passes

• W hen sensing a registration mark on a reflective (shiny) material, mount the R58E at

• C lear materials are poor reflectors of light. When sensing a mark printed on a clear material

Lens Location

The lens may be installed at either of two lens ports (see Figure 6). The lens and the lens port

cap are both threaded and may be exchanged by hand; no tools are required. The lens and

cap both include an o-ring seal.

NOTE: T he lens port cap must be installed on the unused port for reliable operation. Fully seat

over a tension bar or roller, to minimize the adverse effects of web “flutter” or sag (Figure 7).

an angle which places the lens centerline at approximately 15° off perpendicular to the

material’s surface (Figure 8). This “skew angle” will minimize strong direct reflections (which

tend to overwhelm the sensor), and allow the sensor to discern the relatively small optical

contrast offered by differences in colors.

(e.g., a clear poly web), position a reflective surface directly behind the clear material to

return light to the R58E. The printed mark, regardless of its color, then becomes the dark

condition, as it blocks the light from reaching the reflective surface. Most clear materials are

also shiny; it is important to include a 15° skew angle when sensing clear materials (Figure

8).

P/N 122928 rev. C

T

the lens cap to ensure a liquid-tight seal.

T

> 2 seconds

Push Button Enable/Disable (Lockout)

™

T

Registration Mark Sensors

T T T

Installation Notes

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

0.8 seconds

T

T

T

T

T

T

T

T

T

T

T

T

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Figure 6. R58E lens positions

Figure 7. Mounting for sensing opaque non-

Figure 8. Mounting for sensing opaque

Opaque Reflective

Transparent or

Web Material

Tension Bar

Mount the R58E at approximately 15 ° from perpendicular to

Tension Bar

Approximately 15 º

Roller or

Roller or

90º

Mount the R58E Perpendicular to

reflective materials

reflective and transparent materials

non-reflective (matte) materials

transparent and opaque reflective materials

Surface of

Material

Lens

Cap

10 3 mm

Focus Distance

10.0 mm (0.39")

R58E

Opaque,

Non-reflective

Web Material

10 3 mm

Focus Distance

10.0 mm (0.39")

R58E

Cap

Lens