P7S-14F-END-DC24 Omron, P7S-14F-END-DC24 Datasheet - Page 5

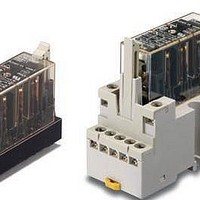

P7S-14F-END-DC24

Manufacturer Part Number

P7S-14F-END-DC24

Description

Relay Sockets & Hardware G7 RELAY TRACK MT SOCKET

Manufacturer

Omron

Datasheet

1.P7S-14F-END-DC24.pdf

(6 pages)

Specifications of P7S-14F-END-DC24

Associated Relay Series

G7S

Mounting Style

Panel

Accessory Type

Track Mounting Sockets

Termination Style

SMD/SMT

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Certified Standards

Safety Precautions

Refer to the “Precautions for All Relays” and “Precautions for All Relays with Forcibly Guided Contacts”.

Wiring

Cleaning

The G7S is not of enclosed construction. Therefore, do not wash the

G7S with water or detergent.

• EN Standards, VDE Certified

• UL standard UL508 Industrial Control Devices

• CSA standard CSA C22.2 No. 14 Industrial Control Devices

• Use one of the following wires to connect to the P7S-14F-END.

• Tighten each screw of the P7S-14F-END to a torque of 0.78

• Refer to the internal connections diagram of the G9S Safety Relay

• Wire the terminals correctly with no mistakes in coil polarity,

EN61810-1 (Electromechanical non-specified time all-or-nothing

relays)

EN50205 (Relays with forcibly guided (linked) contacts)

to 0.98 N·m.

Unit for an application example of the G7S.

otherwise the G7S will not operate.

Stranded wire: 0.75 to 1.5 mm

Solid wire:

Precautions for Correct Use

1.0 to 1.5 mm

2

2

Forcibly Guided Contacts

If an NO contact becomes welded, all NC contacts will maintain a

minimum distance of 0.5 mm when the coil is not energized. Likewise

if an NC contact becomes welded, all NO contacts will maintain a

minimum distance of 0.5 mm when the coil is energized.

(from EN50205)

G7S

5