F9469PC 3M, F9469PC Datasheet - Page 3

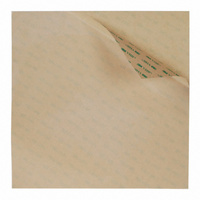

F9469PC

Manufacturer Part Number

F9469PC

Description

TRANSFER TAPE 9469PC 8.5"X8.5"

Manufacturer

3M

Series

VHB™r

Datasheet

1.F9469PC.pdf

(4 pages)

Specifications of F9469PC

Tape Type

Adhesive Transfer Tape

Adhesive

Acrylic, 100MP

Backing, Carrier

Polycoated Kraft Liner

Thickness

0.0090" (9.0 mils, 0.229mm)

Thickness - Adhesive

0.0050" (5.0 mils, 0.127mm)

Thickness - Backing, Carrier, Liner

0.0040" (4.0 mils, 0.102mm)

Width

8.50" (215.90mm) 8 1/2"

Length

8.50" (215.90mm) 8 1/2"

Color

Clear

Usage

Attachment, High Temperature Applications

Temperature Range

300°F (149°C)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

3M6446

70006432028

F9469PCDL

70006432028

F9469PCDL

Application Techniques

Bond strength is dependent

upon the amount of

adhesive-to-surface contact

developed. Firm application

pressure develops better

adhesive contact and thus

improving bond strength.

To obtain optimum

adhesion, the bonding

surfaces must be clean, dry

and well unified. Typical

surface cleaning solvents

are isopropyl alcohol/water

mixture (rubbing alcohol) or

heptane. Use proper safety

precautions for handling

solvents.

It may be necessary to seal

or prime some substrates

prior to bonding.

a. Most porous or fibred

materials (e.g. wood) will

require sealing to provide a

unified surface.

b. Some materials (e.g.

copper, brass, plasticised

vinyl) will require priming or

coating to prevent

interaction between

adhesive and substrates.

Ideal tape application

temperature range is 20 to

38°C. Initial tape

application to surfaces at

temperatures below 10°C is

not recommended because

the adhesive becomes too

firm to adhere readily.

However, once properly

applied, low temperature

holding is generally

satisfactory.

In some cases bond

strength can be increased

and ultimate bond strength

can be achieved more

quickly by exposure of the

bond to elevated

temperatures (e.g. 65°C) for

one hour.

Date : November 2001

9469PC 'VHB' Transfer Tape

This provides better

adhesive wetout on to the

substrates.

CAUTION

The following situations

must be evaluated

thoroughly to determine

whether VHB products are

suitable for the intended

use.

Applications of 4950F which

require performance at

severe cold temperatures

must be thoroughly

evaluated, if the expected

use will subject the VHB

Joining System fastener to

high impact stresses. For

cold temperature

applications from 0 to 10°C

use 4951 (see VHB Special

Feature products data

sheet).

3