D2SW-P2L3M Omron, D2SW-P2L3M Datasheet - Page 5

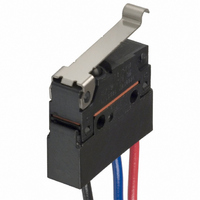

D2SW-P2L3M

Manufacturer Part Number

D2SW-P2L3M

Description

SWITCH SIM ROLLER SPDT 2A WIRE

Manufacturer

Omron

Series

D2SW-Pr

Type

Basic/Snap Actionr

Specifications of D2SW-P2L3M

Circuit

SPDT

Switch Function

On-Mom

Contact Rating @ Voltage

2A @ 250VAC

Actuator Type

Lever, Simulated Roller

Mounting Type

Chassis Mount

Termination Style

Wire Leads

Operating Force

61gf

Microswitch Type

Subminiature

Actuator Style

Simulated Roller Lever

Operating Force Max

0.6N

Contact Voltage Ac Nom

250V

Contact Voltage Dc Nom

30V

Contact Current Max

2A

Actuator

Simulated Roller Lever

Contact Form

SPDT

Ip Rating

IP 67

Current Rating (max)

2 Amps

Voltage Rating Ac

250 Volts

Voltage Rating Dc

30 Volts

Contact Rating

2 Amps at 50 Volts

Ingress Protection

IP67, Watertight

Mounting

PCB

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

D2SWP2L3M

SW812

Z2130

Z2130

SW812

Z2130

Z2130

Precautions

Be sure to read the precautions and information common to all Snap Action and Detection Switches, contained in the Technical User’s Guide,

“Snap Action Switches, Technical Information” for correct use.

■ Correct Use

Mounting

Turn OFF the power supply before mounting or removing the Switch,

wiring, or performing maintenance or inspection. Failure to do so may

result in electric shock or burning.

Mount the Switch onto a flat surface. Mounting on an uneven surface

may cause deformation of the Switch, resulting in faulty operation or

damage.

Operating Body

Use an operating body with low frictional resistance and of a shape

that will not interfere with the sealing rubber, otherwise the plunger

may be damaged or the sealing may deteriorate.

With the pin plunger models, set the Switch so that the plunger can

be pushed in from directly above. Since the plunger is covered with a

rubber cap, applying a force from lateral directions may cause dam-

age to the plunger or reduction in the sealing capability

.

Handling

Do not handle the Switch in a way that may cause damage to the

sealing rubber. When handling the Switch, ensure that uneven pres-

sure or, as shown in the following diagram, pressure in a direction

other than the operating direction is not applied to the Actuator, oth-

erwise the Actuator or Switch may be damaged, or durability may be

decreased.

Wiring Molded Lead Wire Models

When wiring molded lead wire models, ensure that there is no weight

on the wire or that there are no sharp bends near the parts where the

wire is drawn out. Otherwise, damage to the Switch or deterioration

in the sealing may result.

Incorrect

Correct

Incorrect

Sealed Subminiature Basic Switch

Operating Stroke Setting

Set the operating stroke so that the actuator is completely disen-

gaged when the switch is in the free position (FP), and is pushed to a

point between 60% and 90% of the OT distance after the switch is

operated.

Insufficient or excessive pushing of the actuator may result in

decreased switch durability or damage to the switch.

Using Micro Loads

Using a model for ordinary loads to switch microloads may result in

faulty operation. Instead, use the models that are designed for

microloads and that operate in the following range;

However, even when using microload models within the operating

range shown above, if inrush current or inductive voltage spikes

occur when the contact is opened or closed, then contact wear may

increase and so decrease the service life. Therefore, insert a contact

protection circuit where necessary.

30

24

12

5

0

0.1

Inoperable

range

0.16mA

1mA

Operating range for

micro load models

D2SW-P01

1

10

26mA

D2SW-P

100mA 160mA

100mA

100

Current (mA)

Operating

range for

general-load

models

D2SW-P2

1,000

205