862425-1 TE Connectivity, 862425-1 Datasheet - Page 3

862425-1

Manufacturer Part Number

862425-1

Description

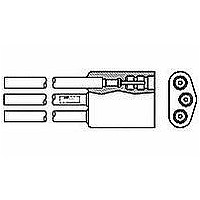

Cable Assembly Power 0.305m 22AWG 3 POS LGH RCP

Manufacturer

TE Connectivity

Datasheet

1.862425-1.pdf

(6 pages)

Specifications of 862425-1

Connector Type

3POS LGH

Cable Type

Power

Gender

RCP

Cable Length

0.305 m

Rohs Compliant

YES

Housing Material

Silicone Rubber

Contact Material

Bronze

Contact Plating

Gold over Nickel

Voltage Rating

7.5 KV

Insert / Contact Gender

Female

Number Of Positions / Contacts

3

Product Type

Receptacle Housings

Termination Style

Wire

Wire Gauge Range

22

Wire Size (mm² [awg])

22

Operating Voltage (kvdc)

7.5

Assembly Length (mm [in])

304.80 [12.000]

Number Of Positions

3

Wire Color

Blue/Yellow/Green

Wire Insulation

Silicon Rubber

Contact Type

Pin

Contact Size

22

Contact Base Material

Bronze

Contact Plating, Mating Area, Material

Gold (30)

Connector Style

Receptacle

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Test Voltage

12 KVDC at 10,000 feet and -15°C to +85°C

Lead Free Status / Rohs Status

Details

Rev O2

Vibration, sinusoidal.

Mechanical shock.

Durability.

Contact engaging force.

Contact separating force.

Therm al shock.

Hum idity, steady state.

Tem perature life.

Test Description

No discontinuities of 10

m icroseconds or longer duration.

See Note.

No discontinuities of 1 m icrosecond

or longer duration.

See Note.

See Note.

20 ounces m axim um .

3 ounces m inim um .

See Note.

See Note.

See Note.

ENVIRONMENTAL

MECHANICAL

Figure 1 (cont)

Requirem ent

EIA-364-28, Test Condition I.

Subject m ated specim ens to 10-55-

10 Hz traversed in 1 m inute with 1.5

m m [.06 in] m axim um total

excursion. 2 hours in each of 3

m utually perpendicular planes.

EIA-364-27, Method H.

Subject m ated specim ens to 30 G's

half-sine shock pulses of 11

m illiseconds duration. 3 shocks in

each direction applied along 3

m utually perpendicular planes, 18

total shocks.

EIA-364-9.

Mate and unm ate gold plated

specim ens for 500 cycles and tin

plated specim ens for 50 cycles at a

m axim um rate of 500 cycles per

hour.

AMP Spec 109-35.

Measure force necessary to

engage using gage 2 to a depth of

.19 inch for 1/2I and 1/2LI and .25

inch for 1I, 1LI, 2I, 3I and 4I.

See Figure 4.

AMP Spec 109-35.

Size 3 tim es using gage 2. Then

insert gage 1 to depth of .19 inch

for 1/2I and 1/2LI and .25 inch for

1I, 1LI, 2I, 3I and 4I and m easure

force necessary to separate.

See Figure 4.

EIA-364-32.

Subject specim ens to 5 cycles

between -55 and 125 C.

EIA-364-31, Method II, Condition A.

Subject specim ens to 40 C and 90

to 95% RH for 96 hours.

EIA-364-17, Method A, Test

Condition 5, Test Tim e Condition A.

Subject m ated specim ens to 125 C

for 96 hours.

Procedure

108-36033

3 of 6